|

|

Forum Index : Electronics : Various aspects of home brew inverters

| Author | Message | ||||

| ltopower Regular Member Joined: 08/03/2019 Location: United KingdomPosts: 64 |

Looks quite inconsistent with the soldering, though it was interesting relative to the heating tests that were done with the FET's, granted in transition zone.. wondered what the heating effect is of not using the thicker leg section. Seen a few boards with FET legs quite long into boards. Poida Im only upto page 34 of the 2nd reading of this thread..... thought this might be of interest. "It uses PD control (like PID control but no Integral component)" I worked in the energy industry for a few years, UK, Australia, USA with the power networks and one of the interests was the impact on grid frequency when a power station (or two) disconnect. Back in 1998 I built some monitoring devices (written in machine code) with GPS ppm timing (two microcontrollers, one for timing, other for data) to measure the relative grid phase timing between points to determine power flow.. Two things that you may need to consider, which you may or may not have noticed, yet.. Large 2 station trips occur rarely the grid is setup to cope with them. LoyYang was an instance that caused some stress in 1999 I think with around 1GW lost.. The rate of change in frequency over the first 1-5 second window can be quite fast and may fall outside your PD tracking rate of change range. Second point is that when these events occur the grid also rings and oscillates for a few seconds before everything stabilises again. I was told by "seasoned engineers" what I was doing was rubbish and I could never measure it. Had a nice chart after the first recorded incident. It is not possible to see it in the base frequency measurements of a single point, unless the grid location is very weak and then some of the ancillary service harmonics may show up. Basically the grid ends up with two sub frequencies, one around 0.2 ot 0.07Hz (standard frequency response services) and the second faster depending on the grid, measuring distance and power flows but around 1Hz. |

||||

renewableMark Guru Joined: 09/12/2017 Location: AustraliaPosts: 1678 |

OK, we all know what a brain surgeon I am, so perhaps you could elaborate on this for me? That smd ferrite #2292371 how exactly is that placed? over the top of the track, bear it to copper and solder close to gate of fet? Don't cut the track to make it in series, but solder it on top of the track to dull unwanted effects? The ZXGD3005 you referenced seems like something that would be great to be incorporated into a future power board, but is retrofitting existing power boards, like the Mad one with the 2292371 an option? Cheers Caveman Mark Off grid eastern Melb |

||||

| Solar Mike Guru Joined: 08/02/2015 Location: New ZealandPosts: 1162 |

Hi There Mark, you are getting there, it's a long learning curve.... Retro fit is definitely an option; Cut the track and solder the smd bead across the gap, close to the gate pcb connection so it is in series with the pcb trace leading to the gate pin. Or if you are inserting new mosfets then get some hollow ferrite beads with a big enough center hole size to fit over the gate lead. As for using the ZXGD3005 Spec Sheet many of the pcb layouts i have posted here use them, for examples of how to mount them, they require copper lands on the supply pins for heat-sinking, they are emitter followers so require 12 volts input drive via a series resistor approx 3k3 to get 11.5 volts out, which is plenty of drive voltage for a mosfet as generally they are spec'ed for 10 volt input signal. Cheers Mike |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

I have seen the *inside* of a HY4008 mosfet, the black plastic housing split apart during a fault event. Anyway, you worry about nothing with regard to leg thickness, the source leg *inside* the housing is connected to the mosfet substrate by two tiny wires. By tiny I mean like hair thickness. Granted, these are just a few millimeters long but its these that blow from excessive heat first. The legs protruding from the body only blow from arcing that often follows a 'bang' event. As long as the soldering is properly done your next worry would be the track size & thickness with regard to heating effects. For the mosfet itself, plenty of heatsink surface is what keeps them cool. Klaus |

||||

| poida Guru Joined: 02/02/2017 Location: AustraliaPosts: 1432 |

This is fantastic to have you here. I have many questions to ask you, but maybe not now. I am aware of the limitations of the PD closed loop performance of those older designs of mine. Can I assume we are looking at mains sync? If so, then.. The mains sync function was always a curiosity for me. I never will have an application for it here at home. The latest code for the nanoverter can obtain sync quite readily and maintain sync with most disturbances I've observed over an hour or so. When sync is lost, signal is sent to a relay to disconnect. When sync is regained, the relay again will signal accordingly to reconnect. Phase error is about 3 parts in a 1000 maximum when "in sync" This is probably not good enough for grid applications. So far, only Mark (RenewableMark) wants to use the mains sync function. He intends to run a generator to provide current to flow backwards through the inverter into the battery, to charge it. I have nightmares due to this concept of his. Why he can not just rectify something like 60V AC and PWM control the DC charge current as it flows into the battery. So much simpler and safer. Active rectifying bridges are simple, cheap and powerful. A toroid to convert 240V to 60V AC is very efficient. PWM charge control scales well into the 100A range now. No exciting blowups. No nightmares... This huge post of mine is meant to be a place to dump bits of this and that we find interesting and educational as we build, or in my case, hack up, an inverter to run some or all of the house AC power. I am not an electrical or electronic engineer. I certainly work as an engineer in my workplace but totally unqualified... I look forward to any contributions you can make here at the back shed. wronger than a phone book full of wrong phone numbers |

||||

| poida Guru Joined: 02/02/2017 Location: AustraliaPosts: 1432 |

Glad to hear you found some value in all this stuff I dump here. If I was looking at needing a large inverter system, I would probably build it in stages. Let's say in your view you need 10kVA. Probably not a good idea to make just one big one, already we know that. Maybe make 3 small ones and have them synchronised. This has many advantages. Firstly, you gain experience building one and testing and using it. When the opportunity arises, you build the next one or two. You could gradually build the house AC wiring as things grow into the planned finish state. I get freaked out when people ask,"well how do I go about making a huge inverter. It will be big. It will be the first one I've made" joining the outputs: 1: use the above aliexpress boards that seem to offer mains sync capability. I would like to see you succeed in that but it's a big project, not like anything we have seen here before. 2: use my nanoverter driver boards, and any of the larger aliexpress boards but with the EGS02 or other controller boards removed. I could modify the nanoverter to bring out a sync pulse, for connecting to slave nanoverter boards. This would be trivial to do and highly reliable. A likely success. Needs 3 nanoverter boards. We would have separate AC output voltage regulation on each transformer. Nice. 3: use my nanoverter boards and build your own power boards, maybe ozinveter style or Madness's boards with the totem pole drives. Again, have one master and 2 slaves. A likely success. Needs 3 controller boards again. A chance that one or other inverter may be over or under AC output setpoint. 4: one nanoverter or other driver board, with it's output fanned out to 3 power boards, but this time using optocouplers to drive the totem pole inputs. No master slave issues. A likely success. You would only need to monitor the output of one of the three transformer outputs, but it probably be best to make sure loads are somewhat balanced between the 3. 5: just have 3 inverters, all merrily banging away at their own frequency and phase. You have the house loads split up into 1/3, each 1/3 going to an inverter. No sync needed. Allows you to incrementally build it and learn as you do it. The aliexpress inverter boards use MOSFET gate drive ICs to control the FET gates. These designs are marginal in my view. The gate drive ICs produce just enough current to switch the FETs. There is certainly NOT enough current in one drive IC to switch multiple banks of MOSFETs, in the case of maybe having 3 boards driven by one gate drive IC. The same goes for the Ozinverter design, it again uses the IR2110 gate drive IC which is fine for switching 4 or 6 MOSFETS but not 3x that. Wiseguy (on this forum) is presently working on a modular power board, with optocoupled gate drive inputs. This permits a large fan-out ratio. My inverters (the one running the house and the spare one, ready when we have a "whoopsie") are based on the 3 x 4 HY4008 aliexpress board, with separate gate drive resitors/diodes/pulldown resistors. I add TVS protection to the gate drive IC outputs, to prevent voltages exceeding the IR2110 specified limits. This makes them much more robust. If you choose to use the board shown above, I highly recommend you get 4 15V TVS (transient voltage suppressors). Cost is about $1 each from RS. The soldering on the FET legs is not much of a problem to my mind. Just as long as it's a good, wet joint, no problems. Tinker, below, notes the internal wiring of the FET is tiny. There is the problem. wronger than a phone book full of wrong phone numbers |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

[quote]Active rectifying bridges are simple, cheap and powerful. A toroid to convert 240V to 60V AC is very efficient. PWM charge control scales well into the 100A range now. No exciting blowups. No nightmares...[/quote] Absolutely ! Combining power sources on the dc side is as simple as it gets. Cheers, Tony. |

||||

mackoffgrid Guru Joined: 13/03/2017 Location: AustraliaPosts: 460 |

Poida, Splitting circuits is the sane way to go. On my off-grid property, I have an outside circuit for pumps, hot water etc - and an inside circuit for the essentials, TV, Air-con .... This is just a cabin atm. 3 hours from a capital city, you need to be self sufficient and have back-ups. Having said that, the fever might kick in, we start making noises like Tim the Tool man, and the desire to make an even bigger inverter , well .... |

||||

| ltopower Regular Member Joined: 08/03/2019 Location: United KingdomPosts: 64 |

Ok, having mixed up a few ideas and comments from the last 52 pages in my head... thought of something that might work.. or not. Warpspeeds commnent of "Something out there will probably be 'bad' enough to break your inverter at some stage." really struck me and made me think. Resonant self destruction from one bad appliance, short circuit switching a breaker on, harmonic distaster in a way not thought about. Taking poidas microcontroller approach is part of the key... Then got me thinking about the power system and frequency response and the way a power grid works. Then looking at ferroresonant transformers and motor generator pairs.. Why not have an inverter that operates at a baseline of 50Hz and actually allows the frequency to droift up and down by say 0.5Hz with sharp loading changes and use a BLDC motor as a flywheel. The ferroresonant transformer I'm not sure about due to the saturation, although a resonant store of some sort ? Every power grid in the world operated for the last 100 years based on the syncronised kinetic energy of all the generators to cope with all the spikes, by allowing the frequency to change... Every inverter made to day (that I know of) keeps the frequency locked or just follows the grid because none of them hava a resonant/kinetic store... Theres the idea... crazy ? |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

I worked for a time at Sola Basic as a design engineer, and designed one of their UPS. All of the Sola Basic products use ferroresonant transformers in their designs, including the 2.5Kva unit I designed for them. This ferroresonant transformer had both a 230v primary, and a second primary that was part of a 50Hz push pull 48v battery powered square wave inverter. The UPS was usually powered from the grid, and the ferroresonant transformer not only regulated the output voltage, but cleaned up any distortion and removed any noise or voltage spikes. If the mains failed, the ferro would continue to power the load for a couple of mains cycles from internally stored energy, until the inverter started up and carried the load. Likewise when the grid came back the inverter was switched off, and grid power restored, all without any break in power to the load. The good thing about it was that the ferroresonant transformer would not only regulate the output voltage, but turn square waves from the inverter into nice voltage regulated sine waves. The bad thing about it was the huge no load power loss of the ferroresonant transformer. Not too serious in a UPS that is usually fully loaded, and only run off batteries for short periods. In this case only about 20 minutes of backup time. Ferroresonant transformer type of inverter would also be far to inefficient at small loads to work as an off grid type of inverter. Another interesting feature of a ferroresonant transformer is you can continuously dead short the output without blowing it up. Above max load, the output voltage pulls out of resonance and the output voltage collapses, without causing a massive loading on the primary winding. Cheers, Tony. |

||||

| ltopower Regular Member Joined: 08/03/2019 Location: United KingdomPosts: 64 |

Been looking at the input choke in relation to the FET spikes and loading saturation, inverter failure under high resistive loads with just a ferrite is likely. Iron core, seprate issues, combination, seems to fit.. was wondering if there was another way to counteract the connected capacitive and inductive loads altering the inverter resonances. I noticed the 'huge no-load power loss' issue and wonderd if they could be combined into something dynamic. After your earlier post mentioning them, curiosity set in. The approach does appear to give a durable solution and the grid switching tests that poida did, was they showing ferro-resonance effect of the grid supply transformers ? With the ferro resonance, I noticed a comment saying they did not like frequency change, as this moves them out of the tuned zone. Could this help dumping energy out, by changing the frequency on purpose ? Do all the losses only come from the primary driving side in saturation... could just the secondary side be taken as a resonant auto-transformer style tank. 3 Phase brushless motor with one phase shifted with the resonant tank on to voltage isolate ? I have seen 3 phase motors run i the past with one phase shifted from a single phase supply, not ideal... wondered if something like this, coupled up kinetic store, could work to filter out those difficult bad applicance issues, by allowing the inverter frequency to shift in order to take energy out of the spinning motor ? Might only need to be a 1kW rated BLDC just to take the edge off the worst of the effects ? Wonder if the no-load losses for the ferro would be smaller or larger ? Throwing some different ideas out to see if we can build a better add-on to cope with the unknown connected item issue. |

||||

| ltopower Regular Member Joined: 08/03/2019 Location: United KingdomPosts: 64 |

The primary filter has been going round in my hear for a while now and been trying to work out the math for it... with some rather odd outcomes if my calculations are right. Looking back at the testing and the effect of saturation on the current spikes in the FET's under load. Normal househols loads will typically have some inductance that mirrors back through the toroid and increases the inductance there.. unless you plug in a lot of resistive loads then pop. The current single 50uH ferrite approach (E65, ground 0.5mm gap, AL 1214, 6.5 turns = 51.2uH) will saturate around 51 Amps. Ok for upto 2.5kW. Larger, seemingly gets a lot more tricky.... above 10kW has to add non ferro ? I'm looking at this because I'm wondering if it is those high surge spikes that would saturate the choke and spike the FET's, if you don't have anough inductive loads attached. EV charging inductance at 7kW, switch the 3kW kettle on ? Next up a larger ferrite (E70, 1.5mm gap, AL 655, 6 turns = 23.6uH, 2 in series) so with the larger gap we are now at 85 Amps and two in series, but 6 turns needed into 273mm2 of area, so enameled copper a must. Ok for upto 4kW. Next up, 2 series 2 parallel E70, 0.5mm gap, 6 turns, 56 Amp. 112A or 5.3kW Next up, TDK B66375 E80/38/20 0.25mm gap (B66375G0250X187), 46 Amps. Next up, TDK B66894 E100/60/28 1.5mm gap, 5 turns (larger are), 12uH per choke. 4 In series..... Ok for 210 Amps or 10kW... 6 turns you only need 3 in series (51uH) and then 7 turns for 2 in series (47uH).. E100 N97 1mm gap, 4 parallel, 8 turns, 49.6uH overall. 43Amps x 4 = 8.2kW. E100 N97 1.5mm gap, 4 parallel, 9 turns, 46.1uH overall. 53Amps x 4 = 10.2kW. Could 2 x E100/60/28 in series then be ideal for upto 10kW (7 turns, 147mm2 window available per turn) ? |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

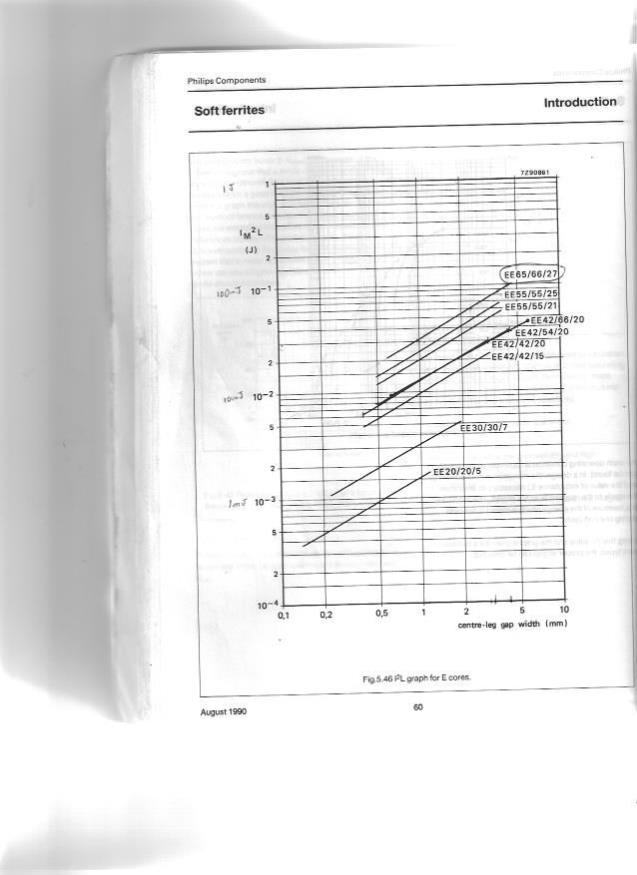

Are you sure about that ? Agree that Al about 1214 with 0.5mm total gap. Agree that 6.5 turns = 51uH at zero current, although half turns are not a good idea. Problem is saturation. You won't get 51uH at saturation. At full theoretical saturation inductance is effectively zero, or at least very much less than at zero current. If you want a choke that works, you need to stop when the inductance begins to fall off, not at full saturation. The book of words (Philips soft ferrites 1991) says L x I squared 20mJ of energy storage for EE65/66/27 cores with 0.5mm gap. That is not a lot. You are claiming 51uH x 51 amps x 51 amps = 132.6mJ which is slightly above 20mJ  Cheers, Tony. |

||||

| ltopower Regular Member Joined: 08/03/2019 Location: United KingdomPosts: 64 |

Thanks for the help, basically, no, I'm not sure.. still on the never ending learning curve. Very interesting page.... thanks, bit more clear now. Ahhhhhhhhh moment..... They provide I/A in the spec. 0.27. So csa min of 529 = 529 x 0.27 = 142 Amps / 6 turns = 23 Amps per turn... 6 turns = 43.7uH @ 23 Amps = 23mJ... ???? Is that how it works ? Feel like I'm back at collage 30yr ago, hahaha.. https://www.mag-inc.com/Design/Design-Guides/Inductor-Design-with-Magnetics-Ferrite-Cores The AL figures are from TDK data sheets. E65/66/27 ? Have not seen that core yet.. I'm using TDK B66388 E65/32/27 data sheet. The formula for the gap I am using is : gap =((4 * PI() * 10^-7) x uH x Amps^2)/(Bmax x 2 x Ac)*1000000 Bmax = 320 Ac = 529 (Ac min for the E65/32/27) This is not taking into account a cliff edge... the inductance falls of though, 2nd ahhhh moment, Bmax is frequency based... (or an ahhhh s** moment). So I/A in the spec overrides the formula or the formula is worng/invalid.. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Energy stored in a capacitor increases at a rate of voltage squared. Energy stored in an inductor rises at a rate of current squared. So the energy storage curves are always given in units of inductance x current squared. So 43.7uH x 23amps x 23 amps = 32.163 mJ As you put on more turns, the inductance rises in proportion to turns squared. Saturation rises with ampere turns so is proportional to the turns. If you do nothing to the gap the stored energy remains the same. Cheers, Tony. |

||||

| poida Guru Joined: 02/02/2017 Location: AustraliaPosts: 1432 |

I have found that the best thing to do when looking at inductance and saturation is to make an inductor tester. You then get to see the inductance change as the core flux increases, particularly near saturation. It is non linear near the extreme end. Are you in a position to do this? I find it hard to follow the magnetics calculations so I just make a choke, test it and decide to use it or not. Maybe add/remove turns and test again. Adjust performance expectations accordingly. On some of the earlier posted ideas of yours, as to how to protect inverters from bad load scenarios, I have just sidestepped the issue. My inverter needs to power my house only. It is not a commercial design, capable of powering anything, with any current flow directions at any time - and able deal with DC loading too. So the inverter of mine is good for 2kVA or so continuous, with peak current spikes 50-60A at 50V DC. I notice the house load sometimes is about 100W from SMPS/fishtanks/etc/NO resistive load and a fridge turns on A spike to 2000W or 45A. This spike in load is about 95% motor turn on loading and likely very inductive. It happens 50 times a day, every day. No problems. We are looking at an interesting problem: do these SPWM inverters scale into the the area of 10kVA and beyond? The capacitor in the LC filter? At 10kVA does it need to be special? Able to cope with huge ripple current? wronger than a phone book full of wrong phone numbers |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

+1 on the inductor tester. And don't forget that ferrite saturates at about 0.35 Teslas, but steel might go to well above 2 Teslas. If you can get the PWM ripple current down low enough to keep the transformer happy, a steel cored choke will be happy too. They are in series and see the exact same dc current and ac flux changes. The exact same skin effect and eddy current problems too. Keep the ripple current very very low, and neither will be a problem in either the choke or the transformer. Big man sized steel core, a decent air gap, lots of turns. Forget about six turns on a tiny piece of ferrite, it ain't gonna work. An inductor tester is an excellent tool for messing around with chokes, there is no substitute for seeing it actually working. Cheers, Tony. |

||||

| ltopower Regular Member Joined: 08/03/2019 Location: United KingdomPosts: 64 |

Inductance tester on the way. Signal generator also on way. Have a scope, power supplies, etc. missing the sig gen to test the transformer resonance with the capacitor. Variac to 'borrow' from my dad so I can experiment with saturation. I have a chinese inverter board sat on my desk (6x4008 legs) and trying to sort out some inductor setup that can cope with around 160-200A (parallel or not). I have a few bits in the shed I want to run and need about 4kW just for them, 10kW surge. The house is on top. The input inductor current limit is key, I think when this is undersized and the inverter sees a surge the ripple can then push the fets over the edge quite easily... missing secondary filters also allow conected capacitance and inductance back in. The AIMS (and various copes) 12kW inverters have 8 FET's and they have chokes about half the size of the transformer... so thinking of options. The E70 (1.5mm gap, 9 turn) will be good for about 1.5kW to test and setup with, while I sort out a larger option. Thought of a different way to test without fet disaster if you dont have a current limited 50V capable bench power supply (which I don't, 30V max). The $15 cheap 1500W boost controlers, take 40A in and 20A out and can be set for current limit, so that's how I will power up initially.. Run it from a cisco 48V 2.7kW power supply I have and limit the boost to 500W at around 52V / 10A. Any issues, 500W should not cause any damage if switched off quick.... My battery pack is 36kWh and effective resistance to the busbar is 5.4mOhm so the voltage does not drop much at all (its lithium titanate as well). 350A test dropped only 1.75V, so this will probably blow the tracks off the PCB if there is an issue once hooked up.. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

And do not forget that as with a transformer, the ac flux density is inversely proportional to turns and core cross sectional area. Big lump of steel, fill it to the max with adequate gauge wire. Then also realise that at 25KHZ the ac flux density will be x500 times lower than at would have been at 50Hz. The ac flux density will be so incredibly low that eddy current loss will be vanishingly small. But all those ampere turns will require a huge air gap, but that is no problem. All these ideas about 25Khz supplies requiring ferrite chokes only applies when you need something really small to fit onto a PCB, the voltage is high and the dc current comparatively low. Then you need gapped ferrite. If the ac voltage is low with moderate to high dc , then maybe powdered iron or permalloy. If the voltage is low and there are tens or hundreds of amps steel wins if you can fit on enough turns to keep the ac flux swing small enough. Choosing a suitable material is a bit of an art form. Don't be misled that every switching power supply application is exactly the same. And a PWM inverter is just a dumb switch mode power supply with the output voltage going up and down like a yo-yo. Many people would recoil in fright at designing a 6Kw switch mode power supply, but think building a 6Kw PWM inverter is dead easy. It isn't. But if you go about it the right way it is certainly do-able. Cheers, Tony. |

||||

| ltopower Regular Member Joined: 08/03/2019 Location: United KingdomPosts: 64 |

'Big man sized steel core, a decent air gap, lots of turns.' The air gap is what I'm getting my head around at the moment, it seems like 3d chess in a way. The second part is trying to source something suitable that has an air gap, which will not cost more than the toroid. The toroid I have is 240/30 6kVA, 14.5W idle. 2.85% regulation, 24.9kg, currently a door stop or foot rest. I was trying to see if the coupling of the ferrite (no load and low load) would work well with a steel (high load and on it's own after ferrite saturated) and trying to work out the air gap implication properly. Found the Joule, airgap charts for the E70 chokes !!! I like to do all the math so I can fiddle with the numbers and double check everything, experiment with what if, how big, how samll.. will it fail if I plug the 250A mig welder in. I know the 12kW plasma will kill it, so that's where I stop. Then I can build.. Inspired by all this I have some testing times ahead, litterally.. |

||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2025 |