Page 29 of 29 Page 29 of 29 |

Since having the Fuse boxes updated and the correct Generator (Inverter) feed cable installed, and still running our larger 3.6kW Water heater, I decided to power our Dual oven and 6 zone Bosh Ceramic Hot plate from the Inverter as well. We were using a smaller desktop oven / air fryer up until now. That means the only thing now on mains is a 15 year old Solar Feed-In Inverter with a 2.8kW array, in other words, it's all feed-in with ZERO mains consumption. The good thing about the Bosh bench top is that it time slices multiple hot plates, so average load is not additive, and the Dual Oven draws less than I had anticipated. The result is that we occasionally see loads of around 13kW, but it could be more if the washing machine was on a Hot wash and set to dry the load when the wash cycle was over, but again, I would have to have virtually everything running. Now this is only a problem for the Battery bank at night, and so far I've still had over 50% charge left in the morning, the Inverter has absolutely no problem, not even a single light flicker with big loads cycling on and off. Obviously if the weather was bad we would be very mindful of power usage, but at the moment we are operating as though we are on Mains, room lights left on (wife), ceramic heaters in bathrooms (it's winter) and a couple of air conditioners, one running all night on really cold nights, 6 security lights and ambient lights in the back yard, in other words, just pigging out on power usage and still not running the Batteries down  BTW We also run a lot of large wood working machinery in our workshop from morning to dusk most days of the week, including equipment drawing 23kW on startup, mostly large induction motors, one big Induction motor has NO startup cap, just a run cap spinning up a massive steel fan impeller. _ Edited 2025-09-11 08:25 by KeepIS |

| |

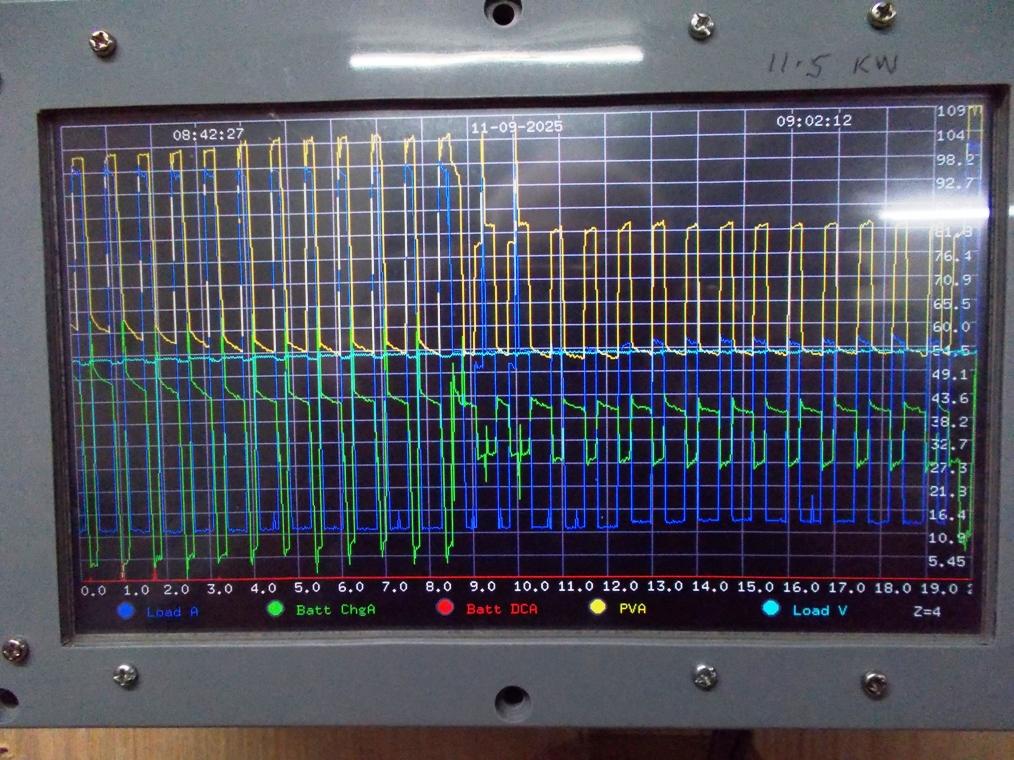

FYI a quick screen photo of the Ceramic Cook Top and other general loads. Blue: Inverter Input current.

Green: Battery Charge current.

Cyan: Battery Voltage.

RED: Battery Discharge current.

Yellow: Solar Current.

Horz scale in minutes updated every second.

Vert scale in Amperes, and in Volts for Cyan trace (Battery Voltage)

Because of the single Vertical scale, these reading are slightly low. IE: Battery volts is actually 54V. Below: DC current from Cook-Top cycling from 4.2kW to almost 10kW.  Below: Cycling from 640W <-> 5.4kW and then 640W <-> 3kW.  Below: The Inverter output Wall power Box, the Tesla kWh meter will accurately calculate Power down to very low power levels (PF does not suddenly go to .58 because of the inability of these colour multi function meters to calculate low Power PF. The "INV AC Direct" switch was for emergency running with just essential devices, I have a feeling this may not be needed, but I have it just in case. These meters were reset recently when the new power box was fitted.  _ Edited 2025-09-11 13:09 by KeepIS |

| |

All going very well, Are you going to be beside the grid, (keep the connection) or go full offgrid (as in removal of the lines and meter) later...  I don't have a decent stove yet, that may be something for later. |

| |

|

Keeping the grid until the 15 year old high In-feed tariffs are shut down in 2028, the In feed connection pays for itself covering infrastructure fees and the credit is also paying for the off-grid system I've built.

I hear they are intending to count any Solar In-feed payments as income, don't have a time frame, and of course charge you for any In-Feed at certian times to pay for them having to install Batteries reserves due to the amount of home Solar feeding the Grid at certian times of the day.

I found out that I can suspend the Mains for 12 months or so without going through a new connection inspection. At this stage the plan is to drop the mains connection as soon as they start charging us or forcing a smart meter, then remove the old In-feed system and replace the panels to add another 5 or 6kW to the Off-grid system.

This morning at 5.30AM I had over 70% state of charge, it's now 8.45 AM and despite early morning loads of 5 to 9kW the SOC is now at 85%, and I'm only charging the Banks to around 95% these days.

I'm amazed at these batteries, some are coming up to 5 years old, Fake EVE Cells, badly assembled (commercial batteries) and were abused by running fully charged for long periods of time etc, a few years back I stripped them and rebuilt the recovered Cells correctly as nominal 48v units.

_

Edited 2025-09-12 10:43 by KeepIS |

| |

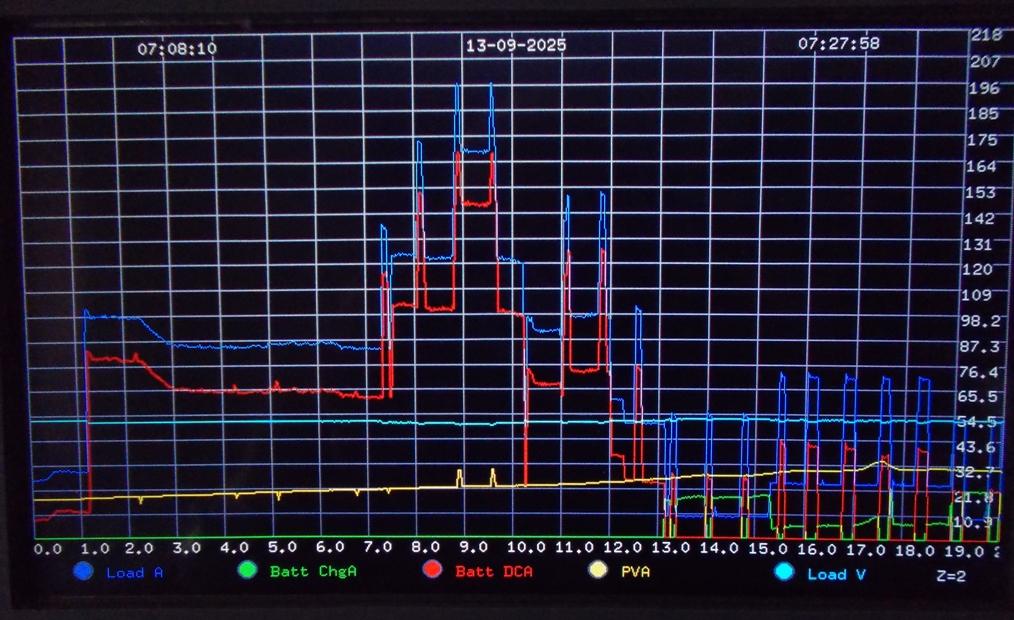

Overcast morning, at 7.18am screen shot of the Inverter peaking at 10.5kW, batteries at 73% SOC after overnight usage. It's now 8.07am, still overcast and solar output is at 3.7kW and rising. Lucky to be living in a good Solar location like QLD.  |

| |

|

The power level of 10.5kW in the last post is wrong, it's actually much higher.

It's being clipped by the Maximum ADC input voltage of the ARM7. I built this 9" touch screen Solar monitor and coded it years ago. Just checking the circuit and code, there is a resistive divider on the input to keep the 500A Sensor voltage in range, it clamps the ADC input keeping the current to a very low value on overload and clamped at around 3.2V.

I need to modify that ADC input circuit and Code (resistive multiplier value) to read to at least 500A @ 3.2V in order to display the correct switching DC currents to match commercial Current Clamp meters, the down side is this makes very low current readings [< 8A] slightly inaccurate. |

| |

|

You may be able to use a digital out/open collector pin to switch the range via another resistor in the lower leg of the divider and have the best of both worlds.

When the ADC value exceeds a suitable limit set the pin low.

When the ADC value falls below a limit determined the ratio of the two ranges set the pin high.

Your software could then either adjust the display to suit the range, or for maximum resolution on the low range, just change the trace colour to show when it is on the high range. |

| |

Hi Phil, good idea and that would be easy to do as well, but luckily I put a big information header in the code file for various Hall Sensor sizes in the Series that I use. I realized that all I had to do was to swap the 400A sensor for a 500A sensor and change a code define. The full scale sensor output voltage stays the same, but the Amperes per volt changes, with the 500A sensor my Limit is now 100A higher. That is still not enough for the really big startup loads but should cover my normal household running loads, hopefully!  |

| |

|

With the higher current sensor installed we peaked at a little over 13kW AC at 7am this morning, mainly resistive loads.

Similar high load levels for short periods (10 minutes) in the evenings, then sits at around 4kW to 8kW for 30 to 50 minutes before dropping to under 1kW after cooking and showers are finished, under 400 watts after 9PM.

_

Edited 2025-09-21 11:07 by KeepIS |

| |

|

I uploaded updated Hex file which have only one change.

The change allows you to use a simple Terminal program with minimal terminal options.

The only change in the Code effects the Terminal application transmit CR-LF setting, when say, TeraTerm terminal APP is connected to the Nano Inverter for accessing the Nano settings Menu:

IE. Windows TeraTerm should now be set to:

Transmit New-Line set to CR (was LF)

Receive New-Line stays at LF, no change.

I find a lot of Linux terminals are either totally stupid for a simple interface to talk to a simple micro with text interface, hence the change, I really should have done this right from the start.

The best simple and clean Linux terminal that I have found is GtkTerm:

In the GtkTerm Configuration Menu:

Tick "Local Echo".

Click Port, be sure to scroll the port selection box right to the end, a number of /dev/ttyS0, ttyS1, ttyS2 etc ports are shown in the list, it does not mean they actually exist, Linux MX, Zorin and Ubuntu etc, all show the Nano USB port as the last entry being /dev/ttyUSB0 in each case.

Set Buad Rate: 57600, Bits: 8, Stopbits 1, Flow none, Parity: none.

In Control Signals Menu: Select Open Port (or press F5)

In View Menu set ASCII.

Once it's all going, select "save configuration" from the Configuration Menu.

NOTE : Do not select "Autoreconnect" in the Configuration Menu:

I found a problem when the program loads and does not find the port at startup, it seems to trash the config file and won't run after that causing a permission denied error, you may not have that problem, but there is really no need to have this option in any case.

Really nice simple little terminal for talking to t he Nano controller.

.

Edited 2025-12-01 18:46 by KeepIS |

| |

|

FYI update: It was in May 2023 that I finished building the first Wiseguy Power board, it replaced a big China power board in first my DIY Inverter, that WG PWR board has been running since then.

It transferred into the Dual Inverter when it was built around March 2024, I had a spare V1 board which became the second board in the Dual stage INV. I kept the later tested V2 & V3 boards I built for the Dual inverter as backups.

I don't know how much power has passed through it, but it ran a year as a single Inverter before I finished the Dual inverter, we used over 4.5 mWh running 24/7 in the past 5 months.

That is climbing faster now as the property, home and workshop are fully electric and everything has now been running 100% off grid. The Nano controller-Inverter has been 100% reliable.

. |

| |

Page 29 of 29 Page 29 of 29 |