|

|

Forum Index : Windmills : BLDC DD 3-Phase AC Induction Generator Build

| Author | Message | ||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

Well maybe that's a reasonable assumption, but it's an expensive one. 3-phase high voltage 50A primary to low voltage secondary transformers are damn expensive. |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

So, how uniformly made are the windings that you managed to rewire? How come you didn't want to increase the number of windings per pole? How much do the windings (@ 0.8mm dia) protrude above the poles? Is it the same as the aluminum was? What was the dia of the Al wire again? 1mm? 0.9mm? |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

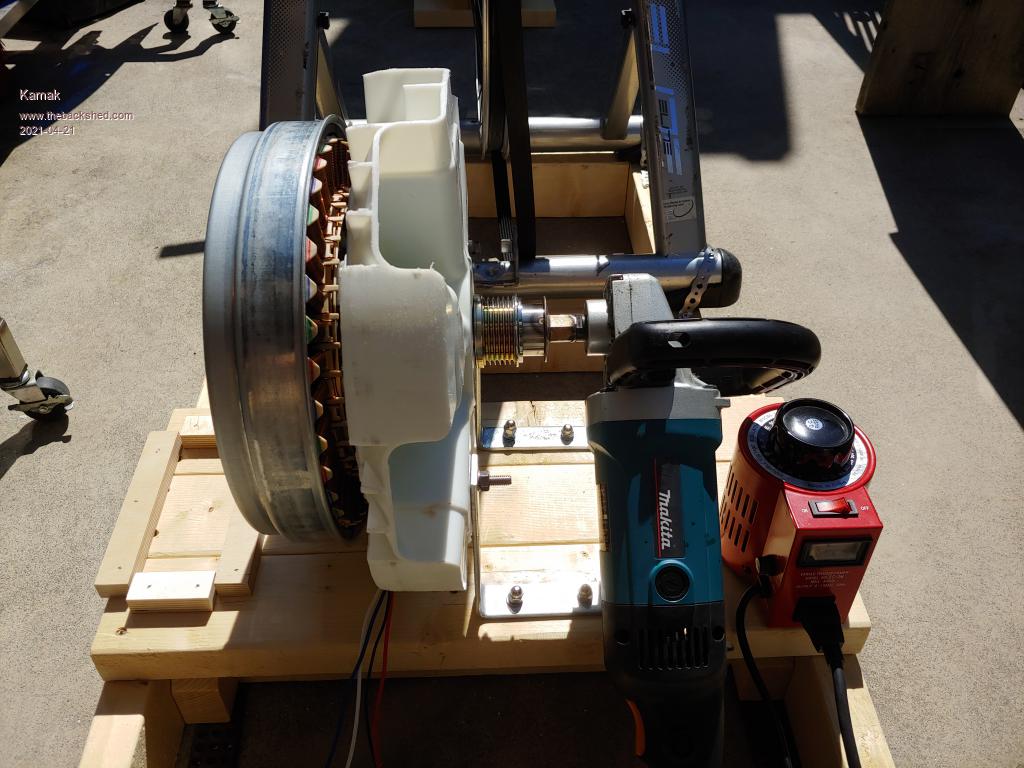

A new method of steady-state measurable RPM.  |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

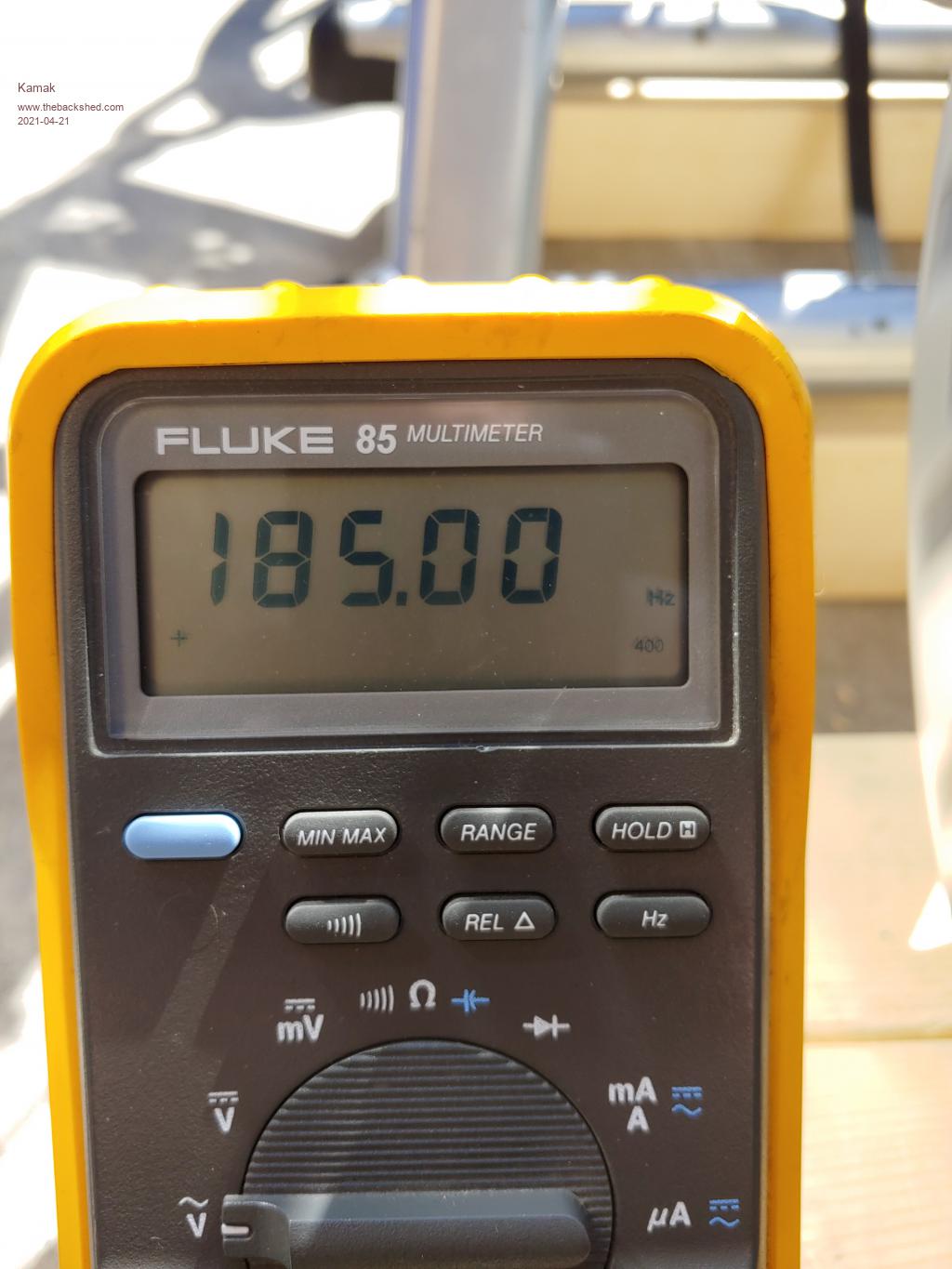

185hz = 462.5 rpm 185/24 pole pairs x 60sec. = 462.5rpm  |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

The stock voltage Vp output of one phase at 462.5rpm.  |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

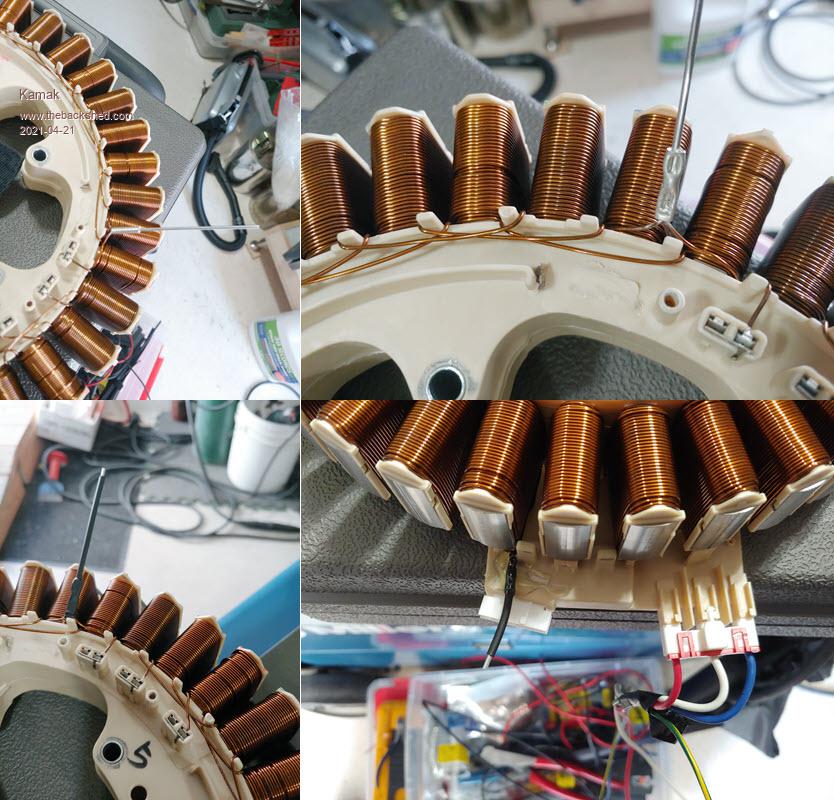

Crimped on a common point connection.  Edited 2021-04-21 10:33 by Kamak |

||||

| Technophiliac Regular Member Joined: 18/12/2020 Location: New ZealandPosts: 89 |

What's the voltage drop to with a load on e.g. - PTC heating element or ceramic dump resister - or? Davo, Wellington. You can have it perfect, on time, and at the best price. Choose any two. |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

I haven't gotten that far yet. I'm still waiting for the 50A/1200V 3PH rectifier to show up. And I'm trying to figure out what size dump resistor to buy. Probably a 750 - 800W unit? But what ohms? I'm thinking about running this thing at 200V approx. What are your thoughts? |

||||

| Technophiliac Regular Member Joined: 18/12/2020 Location: New ZealandPosts: 89 |

Brief reply - Remember a dump load resister does not need rectification to use - but if 3 phase AC then 3 symmetric dump loads might be usefully used. One might say this is complex, plainly you are not troubled with complex. Would need someone more clever than me to speculate the voltage under load, suffice to say I expect it to be lower, and may be surprisingly low - if my generators are anything to go by. I also observe generators have a rating, typically the Chinese rate their turbines at wind of 11 m/s or so(!) My point is a generator is better rated and understood with its power curves in a specific scenario.... taking into account particularly speed / torque and load. If it were me I would just hook up some sensible loads and measure what happens to get a scoping of what we have.... I am not saying my approach would be better, its realistically described as the quick and dirty approach, nothing more. Davo, Wellington. You can have it perfect, on time, and at the best price. Choose any two. |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

Well, I thought you would put a dump load resistor after the rectifier. This was just a pure guess on my part. I really have no idea. I'm still learning as I go here. I don't really want to hook up three loads to three phases. So I was going to load it after I got the rectifier (soon I hope) Any reply is greatly appreciated, so thanks for anything you can add. I know it's kind of quiet over here in the wind turbine threads now. lol Edited 2021-04-21 13:13 by Kamak |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

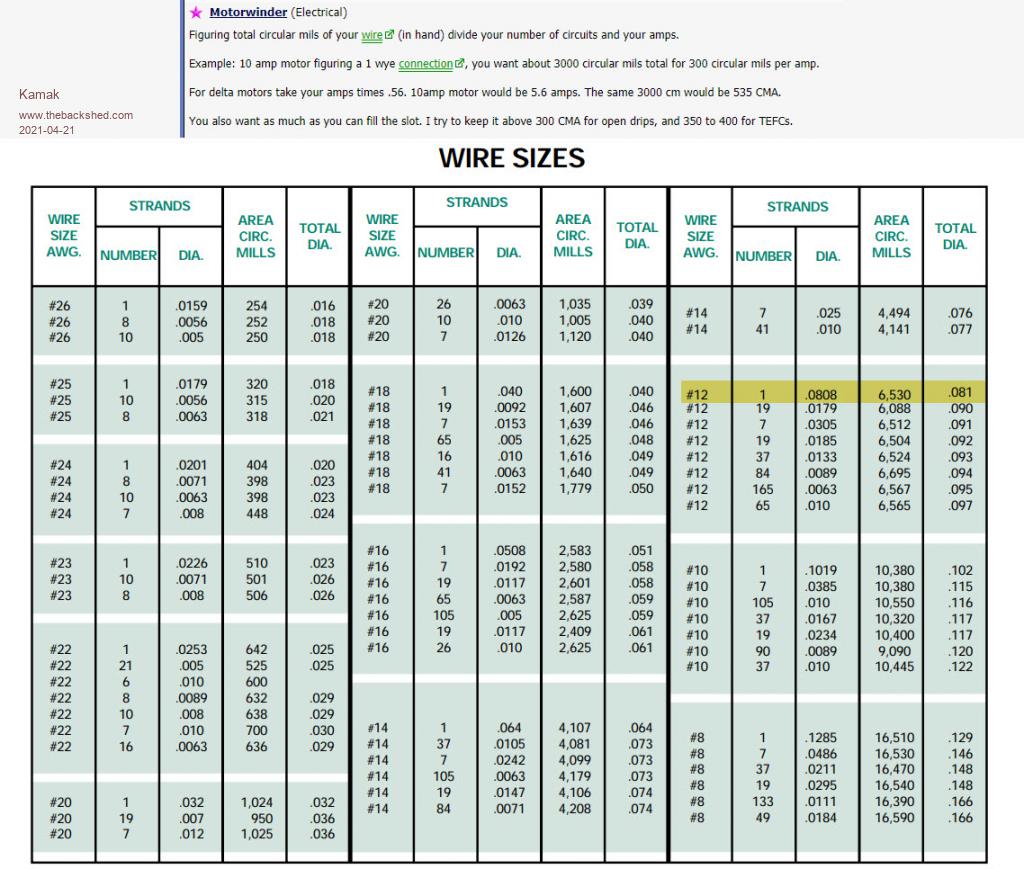

Selecting Wire Size for a 50A Star wound 3PH Generator Using a good rule of thumb of 300-400 CMA (I'll use 400) per Amp Approx 16A per single star leg? 16 x 400 = 6400CMA from the chart, 6400CMA is close to a 12gauge single strand wire with 6500CMA.  Edited 2021-04-22 06:12 by Kamak |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

confirmation of RPM through two methods of measurement. Digital tachometer and electrical AC frequency. Approximations due to fluctuating loads. Tachometer reading of 205/209.6 RPM A voltage reading of 55.5V DC A frequency reading of 85.4Hz 85.4 Hz(cps)/24 N|Spc x 60 spm = 213.5 rpm cps(cycles per sec), N|Spc (pole pairs per cycle), spm (sec per minute)   Edited 2021-04-22 06:39 by Kamak |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

It was a small short 4s (8MB) gif file, but it doesn't upload as a gif.   Edited 2021-04-22 07:44 by Kamak |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

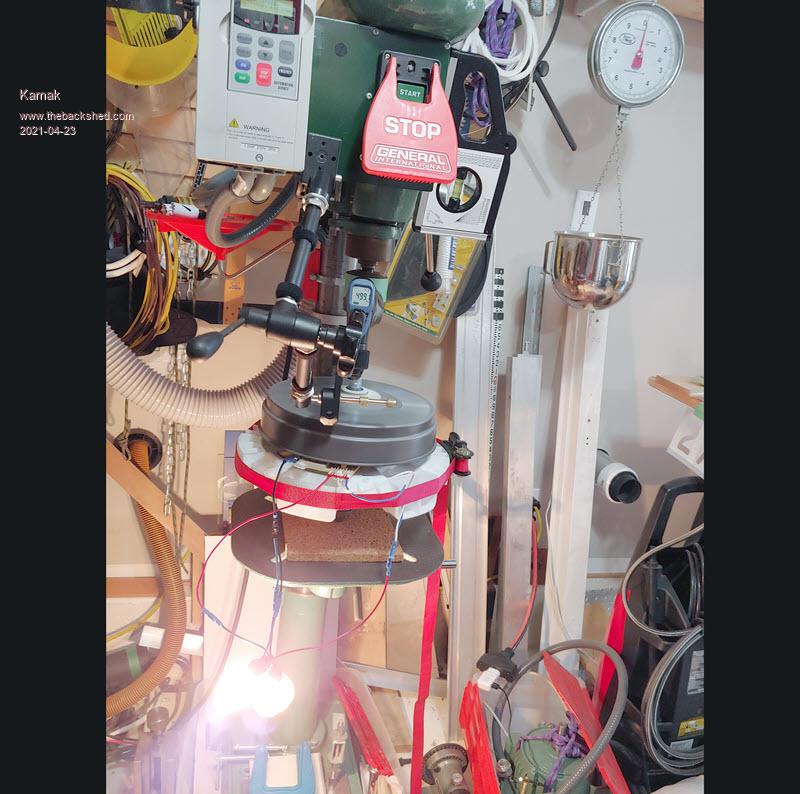

Better Test Bed  Edited 2021-04-23 05:47 by Kamak |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

Stock rotor/stator: (10ohm loads(100W incandescent bulbs), 120V, 0.919A)x2, 500 rpm, 110W(x2),Single phase ea @ 220W total. I could put another bulb on leg 3, I just didn't have one. So 330W @500rpm could be done. Obviously, I need to increase the magnetic flux density. This needs to be 800W at 200rpm. I have a 2 ohm, 750W resistor coming, and the 3 phase rectifier. Waiting, waiting, waiting...   Edited 2021-04-23 11:21 by Kamak |

||||

| Technophiliac Regular Member Joined: 18/12/2020 Location: New ZealandPosts: 89 |

Davo, Wellington. You can have it perfect, on time, and at the best price. Choose any two. |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

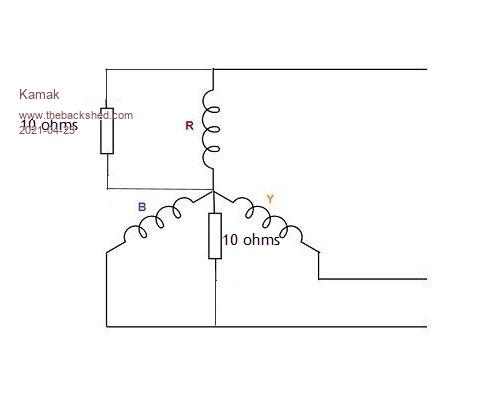

Selecting Wire Size for a 50A Star wound 3PH Generator (even if it could achieve this) @ 24V @1200W Using a good rule of thumb of 300-400 CMA (I'll use 400) per Amp Approx 16A per single star leg? 50/3 = 16.66 16.66 x 400 = 6664CMA from the chart, 6664CMA is close to a 12gauge single strand wire with 6500CMA. But.... 50A Star wound 3PH Generator @1200W (even if it could achieve this) @ 48V @1200W That would be 25A For a (3x4C)3, that's 9 parallel legs @ approx. 2.3A per leg. 2.3 x 400 = 920CMA from the chart, 920CMA is close to 20 gauge (0.03196inch 0.8118mm) single strand wire with 1024CMA. But if I select for the worst-case scenario, with 1200W @12V that would be 100A For a (3x4C)3, that's 9 parallel legs @ approx. 11.11A per leg. 11.11 x 400 = 4400CMA from the chart, 6530CMA is the nearest single strand wire to 4400CMA which is 12gauge (0.08081inch 2.053mm). That's much higher than 4400CMA, but it's the nearest. standard gauge single strand size "above" the CMA requirement. There would be no worries about voltage drop or heating using it for 12V service. (3x4C)3 @48V is approx 150 RPM (from the F&P chart)? Unknown for a Samsung BLDC Generator with changed-out magnets and rewired with the proper gauge copper wire. 3Wiring.jpg) Edited 2021-04-24 00:54 by Kamak |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

http://www.thebackshed.com/forum/ViewTopic.php?FID=2&TID=13733#167708  Edited 2021-04-25 03:31 by Kamak |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

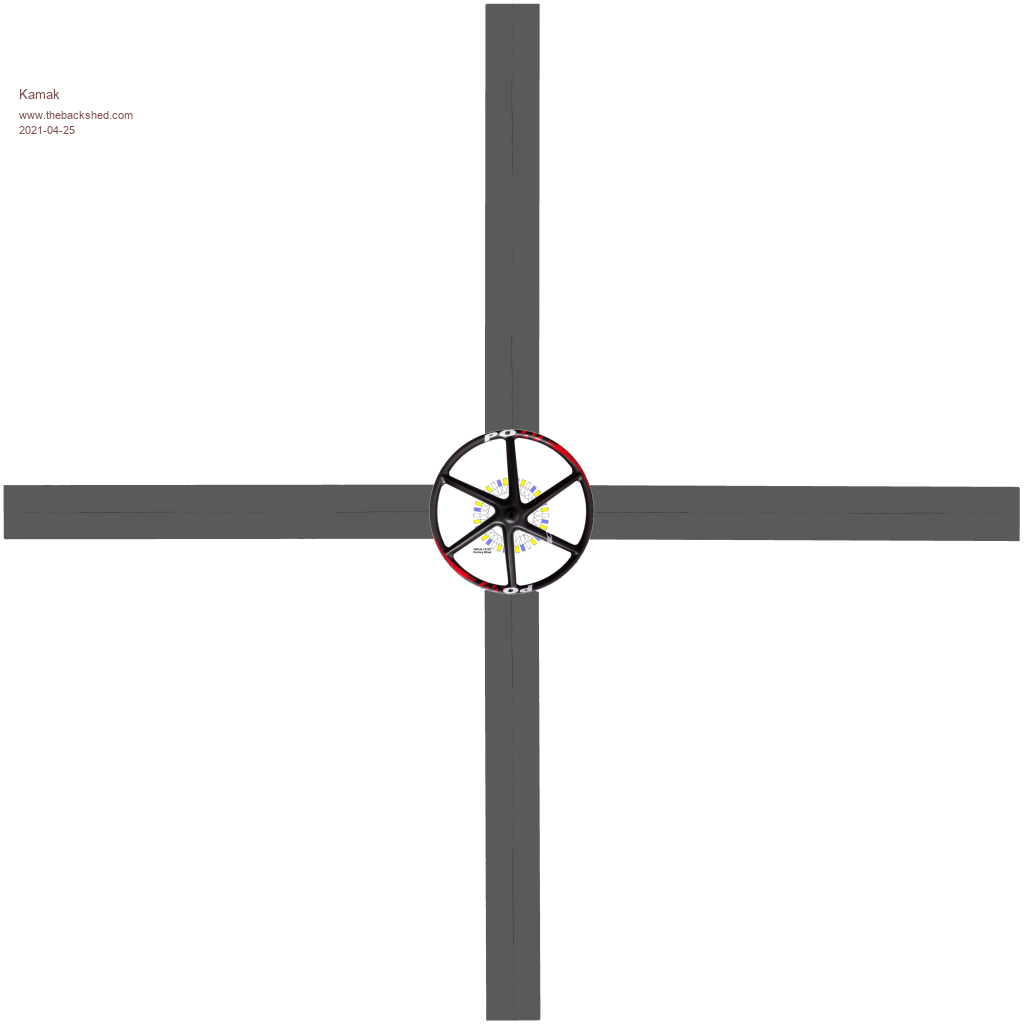

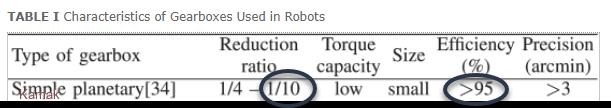

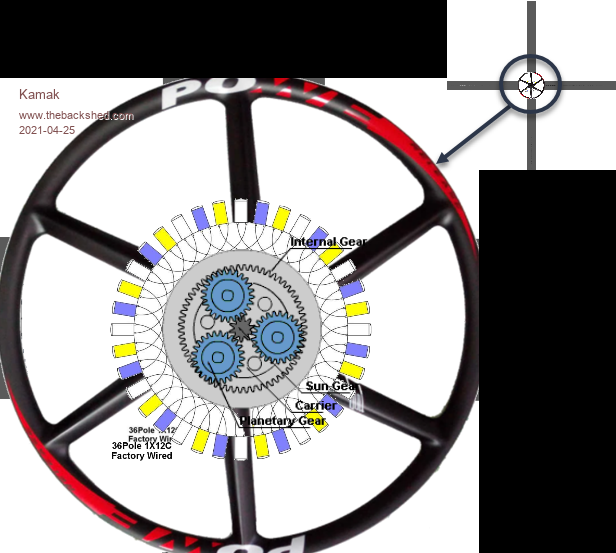

Back driving the planetary gearbox using the RING gear is possible, all be it with higher torque requirement, but possible with the right sized turbine blade lengths, combined with the larger diameter Blade-Hub (ie. a 29" bike rim) 10:1 Ratio = 100rpm Blade-hub:1000rpm Rotor   Edited 2021-04-25 05:28 by Kamak |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

Hopefully, by early next week, I should have: 1) 1x additional rotor - to start changing out magnets. 2) 125x 5mmx5mmx5mm new N52 Neo magnets (for prototyping) http://www.thebackshed.com/forum/ViewTopic.php?FID=2&TID=13689#167341 3) 2x 3 phase 1200V 50A rectifier 4) 1x 2ohm 750W load resistor Edited 2021-04-25 06:27 by Kamak |

||||