|

|

Forum Index : Windmills : BLDC DD 3-Phase AC Induction Generator Build

| Author | Message | ||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

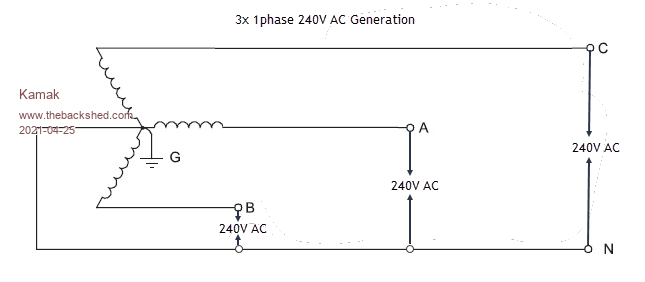

High RPM, high voltage turbine using a 10:1 ratio planetary gearbox @100 rpm prop speed = 1000rpm rotor speed, 240V 3x 1phase AC outputs.    Edited 2021-04-25 14:21 by Kamak |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

Some kind of proportionally applied electromagnetic braking to maintain design tolerant rpm range in higher than acceptable wind speeds, with dead-man (power failure) full-stop braking. https://www.youtube.com/watch?v=zytA5sspA1k&t=12s |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

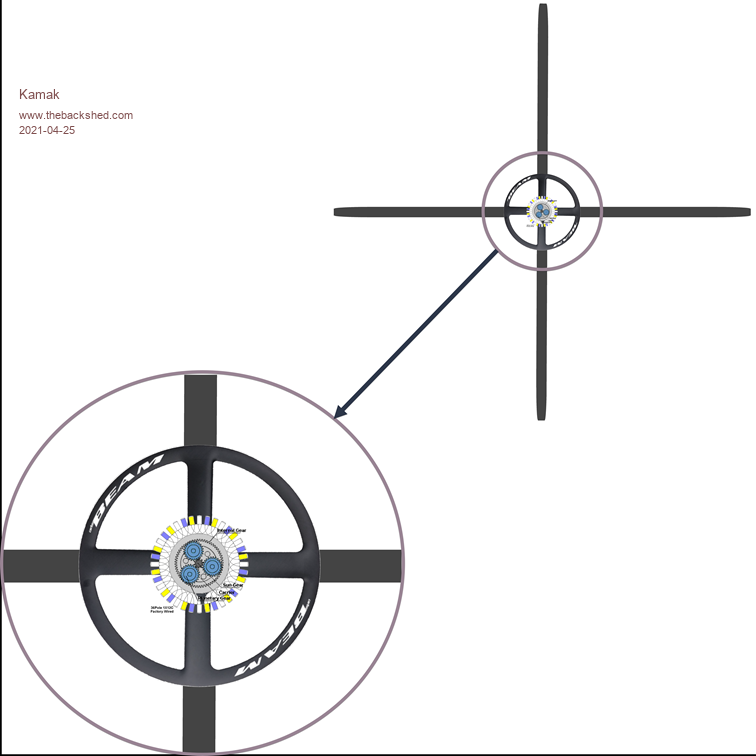

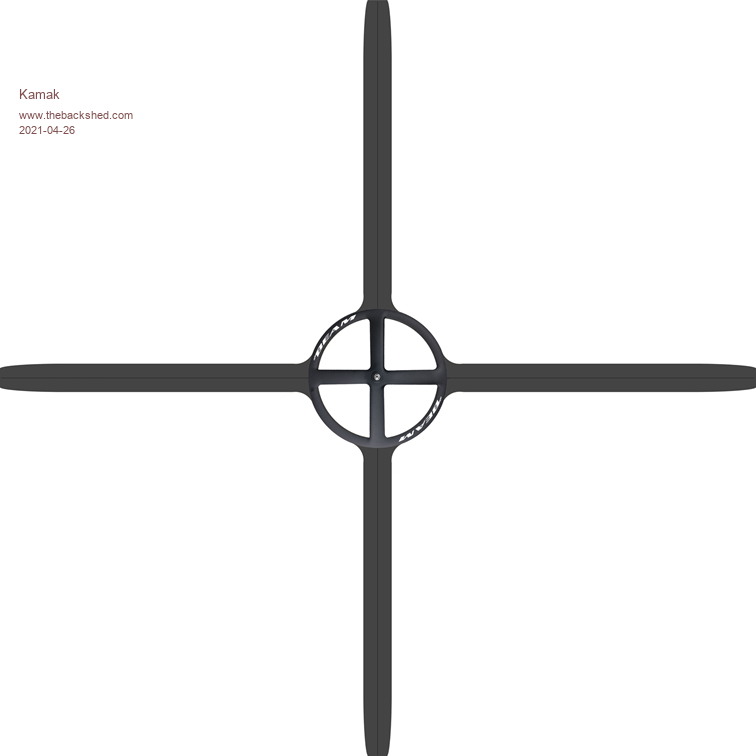

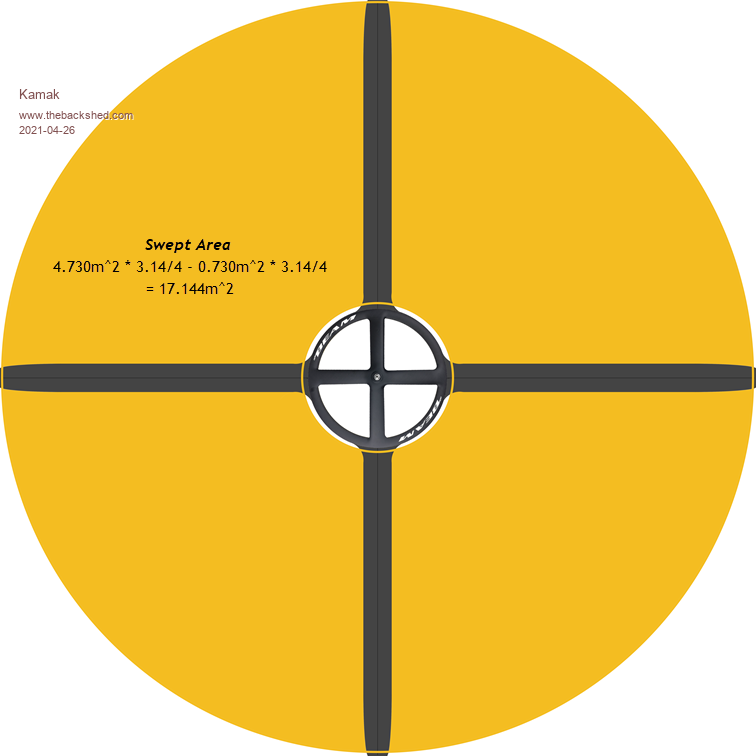

4730mm Dia 4 blade prop. High torque @ low rpm. This is just a guestimate at this point, but I think I'm in the ballpark.  Edited 2021-04-26 04:11 by Kamak |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

910 RPM on a Samsung Wf210anw produces 240V AC across neutral and any one winding.  |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

|

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

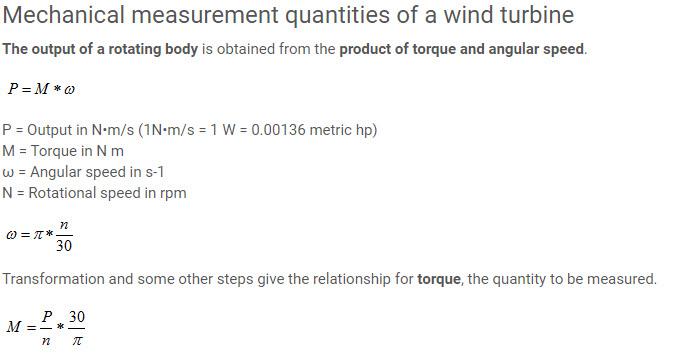

Generator: P=1200W Gear unit: 10:1 (>95%) RPM: n=910 M = 1200/910 * 30/3.14 M=12.598Nm @ 91 RPM, MD = 125.98 Nm (10x) Applied(required) by the Wind Tubine Blades @ 910 RPM, MD = 12.60 Nm (1x) Applied to the Generator  The equation for Wind Power(P) is given by P= 0.5 x p x A x Cp x V^3 x Ng x Nb Where: p = Air density in kg/m^3 A = Rotor swept area m^2 Cp = Coefficient of performance, 35% V = wind velocity (m/s) Ng = generator efficiency, Unknown Nb = gear box bearing efficiency >95% p = 1.22527 A = 17.144m^2 Cp = 0.35 V = 1.666m/s (6kph), V = 5.55m/s (20kph) Ng = 1 Nb = 0.95 Wind Power(P) is given by P= 0.5 x 1.22527 x 17.144 x 0.35 x 1.666^3 x 1 x 0.95 Produced Power P = 16.148 W Wind Power(P) is given by P= 0.5 x 1.22527 x 17.144 x 0.35 x 5.55^3 x 1 x 0.95 Produced Power P = 1,706 W Edited 2021-04-26 14:29 by Kamak |

||||

| Technophiliac Regular Member Joined: 18/12/2020 Location: New ZealandPosts: 89 |

Perhaps I missed it and apologies if I did: what V (wind speed m/s) are your using or calculating as required in this scenario? Davo, Wellington. You can have it perfect, on time, and at the best price. Choose any two. |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

Sorry I was playing around with that for a while. That was giving me some head-scratching. There is a massive drop in power produced at 6kph wind as opposed to 20kph winds. So much so, I'm still hesitant that I calculated it correctly. But I think it is correct. It's those cubings, get you every time. P = 126 N.m/s, 1200W @ 910 rpm, 240V @ 5A p = 1.22527 A = 17.144m^2 Cp = 0.35 V = X m/s Ng = 1 Nb = 0.95 126= 0.5 x 1.22527 x 17.144 x 0.35 x X^3 x 1 x 0.95 V = (126/0.5 x 1.22527 x 17.144 x 0.35 x 1 x 0.95) v3(cube root 3) v = 3.402m/s = 12.25kph 12.25kph required to produce 1200W by the generator (240V @ 5A) through a 10:1 planetary gearbox. Edited 2021-04-26 15:11 by Kamak |

||||

| Technophiliac Regular Member Joined: 18/12/2020 Location: New ZealandPosts: 89 |

Sounds correct to me, see the graph I posted recently which I expect is more or less typical in overall shape for most micro generators. You could graph your function to compare. I will be interested to see the Power values you get at say 10, 12, 14 16 and 18 m/s. Davo, Wellington. You can have it perfect, on time, and at the best price. Choose any two. |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

Could you steer me in the direction of the graph you posted? Isn't 10, 12, 14 16 and 18 m/s rather fast winds? 18m/s = 64.8kph. I think I would have to put the brakes on at 30kph, 8.3m/s But as a water turbine, that's could be interesting, indeed. |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

I would think it will take a fair bit of torque to overcome the initial moment of inertia and mechanical friction, from a dead stop. especially with a gearbox in line. |

||||

| Technophiliac Regular Member Joined: 18/12/2020 Location: New ZealandPosts: 89 |

Indeed! https://www.thebackshed.com/forum/ViewTopic.php?TID=13696#167226 And to your earlier post many turbines are designed to survive in 40 - 45 m/s winds. Maybe you get winds like that between many moons indeed, but when they come...do you want it going boof.....or perhaps something a little safer? Recalling the cube, how much wind will your brakes stop? Davo, Wellington. You can have it perfect, on time, and at the best price. Choose any two. |

||||

| Technophiliac Regular Member Joined: 18/12/2020 Location: New ZealandPosts: 89 |

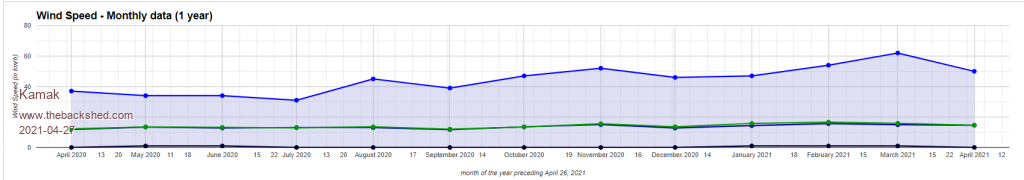

I wonder how much wind it will, as you say, start turning and making power, and plainly you are going to limit power generation at 8.3 m/s which really asks the question what wind band / range do you anticipate this will work within? Seems to me its being designed to work in a very narrow wind band. Have you put up a wind speed logger at your proposed site or looked at applicable locally logged wind speed data? Davo, Wellington. You can have it perfect, on time, and at the best price. Choose any two. |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

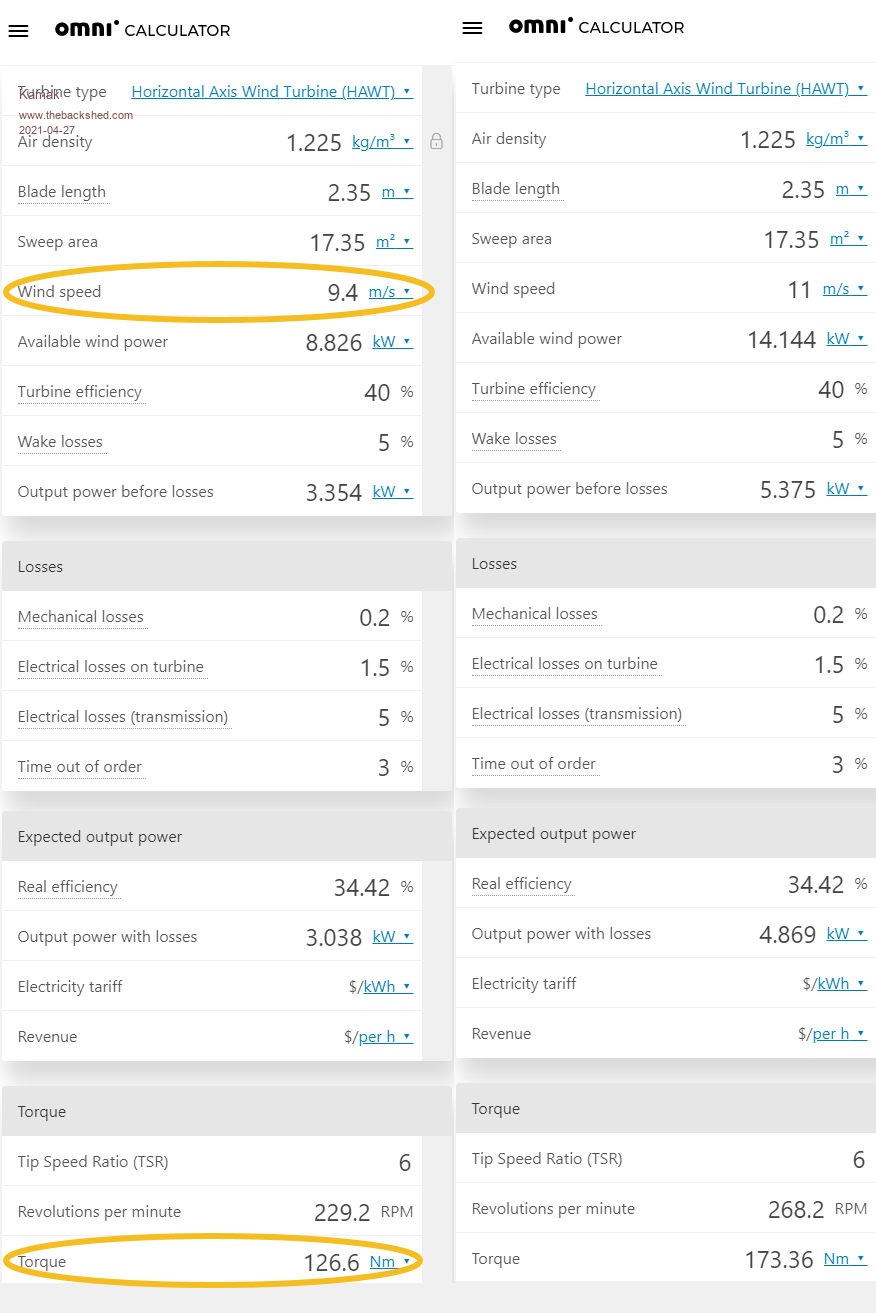

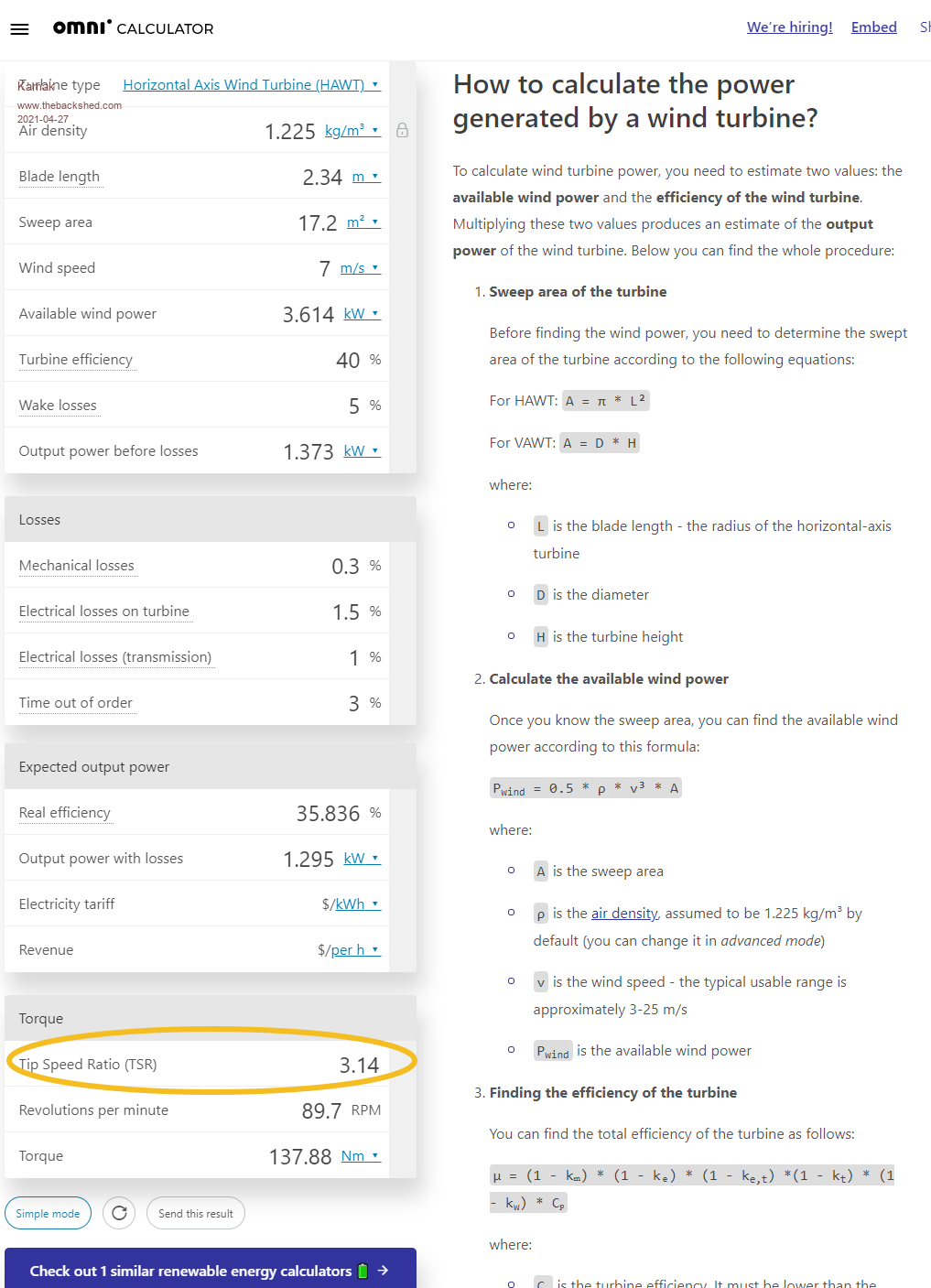

Well, first, I see some glaring discrepancies in my calculation vs an online calculator, like this one. https://www.omnicalculator.com/ecology/wind-turbine This is, most likely more realistic, but there must also be some glaring issues with my manual calculation that has not accounted for something, that I can not see right now. For one thing, my use of the power and torque required to produce the required rpm at the generator is messed up. Firstly, power in is power out, all-be-it with losses, so that's an obvious one there. There's no such thing as a free lunch, right? We can't "amplify power" through a mechanism, we can only capture as much as possible and transfer it, transform it, with as little losses as possible. So, therefore, yes the gearbox will amplify the rpm, but at a power loss of less than equal to its output. So I have to calculate the power required, just to start and maintain velocity, of just the gearbox alone, and the power to overcome its inherent inertia against accelerate. Wind Turbine Blade Efficiency and Power Calculation with Electrical Analogy Therefore, I'll need the rotor's power output of approx 1.7 x 1200W (as per standard practice for wind turbine calculated losses), plus, the power loss through the gearbox. Edited 2021-04-27 01:17 by Kamak |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

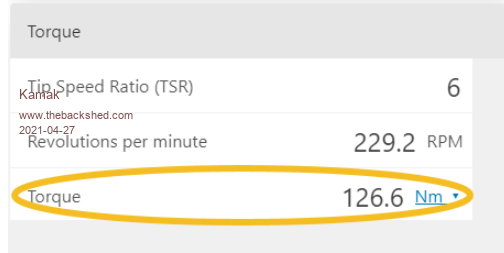

If this calculator is correct, then the minimum rotor power required to deliver the minimum torque to the gearbox to maintain 1200W at 910rpm, 240V ac @5A single phase per winding, is: 3.038KW to make 1.200KW, 2.5:1 reduction. 34Kph. Not including startup and acceleration torque. how-to-calculate-the-power-generated-by-a-wind-turbine The second chart is the local monthly avg. wind speed.  Obviously, the rotational speed would not be correct due to the minimum torque required to spin the gearbox at 91rpm @ the ring gear to produce 910rpm at the sun gear. https://www.hbm.com/en/3108/torque-measurement-in-wind-turbines/   Edited 2021-04-27 04:19 by Kamak |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

Well, this is actually starting to look more sensible and realistic. I had to recalculate for a 4 blade rotor. 4 x pi/4 = 3.14 TSR More torque at less speed.  |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

Well yeah, I do intend to make it survive most common weather conditions, but as for useful excessive power, still within safe rpm range, but that is above the voltage range that it is designed for, dump loading into something useful like hot water heating would be a good method I suppose. At the moment, I'm only getting 7.7V max. at 2.7A max. ac (20.79W) maximum through a 2.7 ohm 750W resistor across one winding and neutral at 1000RPM. There must be such a minimal ability for the generator, with its combination of existing stock magnets with low magnetic flux density and the number of wire wraps per stock star leg, that it can not produce many amps through such a low resistive load. The three winding each have 6.2 ohms of internal resistance. The light bulb I used, the other day, was 10ohms - cold. it was only a 100W capable device and I was able to put approx 120V at approx 0.919A through it at 500RPM. 120x0.919 = 110.28W. 120/0.919 = 130ohms - hot. I need a higher resistive load capable of higher wattage with a minimum of 2.7A capability, but I can't exceed the RPM of 1000. Open circuit voltage across any winding and neutral is 240V @910RPM @500RPM, the voltage across one winding and neutral was 120V and 0.9A with a 130ohm dynamic resistor, a bulb, temp dependant. 32ohms = 240W/2.7A^2 88ohms = 240V/2.7A, P = 240x2.7 = 648W, Maybe that's the one, 88ohm resistor capable of 750W I found an off the shelf resistor 82ohms, 750W max, V = 82 x 2.7 = 221.4V, 221.4V^2/82ohms = 597.78W, If at 240V^2/82 = 702.439W but that suggests an amperage greater than 2.7A, which I don't think it will produce. That would be 240V/82ohms = 2.927A. 240.5V/916RPM = 0.26255V/1rpm open circuit. Check: 0.26255 x 500rpm = 131V open circuit. 366.5Hz = 366.5/24poles x 60sec = 916.25RPM  Edited 2021-04-27 16:12 by Kamak |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

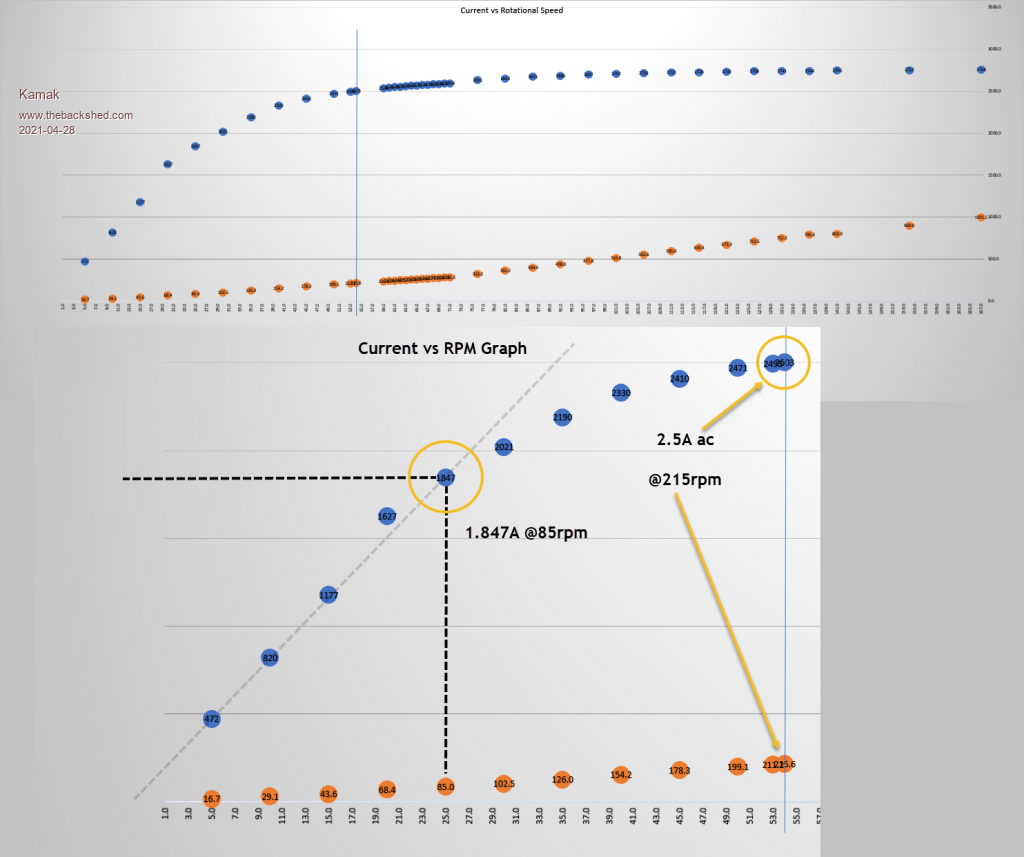

BLDC motor out of a Samsung Wf210anw washing machine https://issuu.com/heydownloads/docs/001___samsung_wf210anw_wf220anw_service_manual_rep 36 pole(coil) aluminum wound stator - 19ga (0.03589", 0.9116mm) wire, (unknown wrap count per pole as of the start of the build) 6.2 ohms resistance per total of the 12 pole coil count, for each of the three-phase legs. 30 wraps on the top layer of each pole. Estimations of coil wraps per pole: visibly 30 wraps on the top layer of each pole coils. Estimation of 5 layers = 150 wraps? Correction, it can not be an uneven number of layers of coil wraps, it must be multiples of 2, due to how the coils are constructed. They begin at, and end at the hub of each pole, hence multiples of 2 layers per completion. Therefore there must be either 4 layers or 6 layers. 19 ga aluminum wire has a 14.6-ohm resistance per 1000ft. The measured resistance is 6.2 therefore 6.2(1000)/14.6 = 424.65ft/leg, 424.65/12 poles = 35.38ft/pole approx. 35.38ft x 12 inch = 424.65 inch/pole coil, 424.65/150 wraps = 2.83 inch per wrap avg. Seems reasonable. Correction, 424.65/(30x4) = approx 3.5"/wrap, 424.65/(30x6) = approx 2.35"/wrap. 4 magnetic poles in each of 12 magnetic bricks (NSNS x 12 = 48 poles) Magnetic flux density per magnet is approx 1750 - 1800 Gauss at their highest peak regions. 2.7 Ohm Load Resistor Star Winding, Single phase to Neutral Conclusion: approx. 200RPM @ 2.5A, Maximum Return vs Cost-Benefit Point, really starts to taper off.  Edited 2021-04-28 06:17 by Kamak |

||||

| Technophiliac Regular Member Joined: 18/12/2020 Location: New ZealandPosts: 89 |

My understanding is you are getting this using your bench drill press? It might be interesting to measure the bench drill torque, which will be a function of the current / power its (the drill press motor) pulling / drawing when you are driving the dump load at a notional 20.79W - and how much energy is going elsewhere? 20W running a generator at a proven 1000 rpm seems unexpectedly low to me. One back yard way of getting more resistance would be to use long runs of cable in series with your resister. Davo, Wellington. You can have it perfect, on time, and at the best price. Choose any two. |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

You have to see the other post I've made, with regards to my suspected reasons for the 2.7ohm resistor, the 100W light bulb, and the graph above. The resistor is too low, compared to the resistance of the internal windings, I believe. It's just like shorting the two ends of the windings (neutral and #1, say) through the meter, nearly no voltage. It's capable of producing lots of voltage, with a max of 2.7A. The light bulb proves that it can produce at least 120W. I demonstrated it. I just need 88ohms at 700W. So I'm getting 11x 8ohm resistors capable of 100W each (88ohms @1100W). 2.7A^2 x 88ohms = 641.5W through one winding @ approx. 240V. But the graph says that gains after 2.5A are negligible. and that occurs way down in the rpm range. approx 200rpm. This makes it more practical to use a 2:1 ratio planetary, at 100rpm input. So maybe at around 2.5A, 2.5A^2 x 88ohm = 550W per winding = 1650W @ 220V (x 3 windings), 2.5A x 88ohms = 220V. Proven with test hopefully. approx. 0.26255V/1rpm (open circuit). 220/0.26255 = 837.9rpm Maybe back up to an 8:1 planetary I'm not sure at what rpm it will reach 2.5A with an 88ohm load Three step down transformers, one for each winding. Edited 2021-04-28 13:40 by Kamak |

||||