|

|

Forum Index : Electronics : What epoxy are you guys using for your torroid builds

| Page 1 of 2 |

|||||

| Author | Message | ||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 951 |

I have read all over the place that you use epoxy resin during the process of building your torroid transformers. I saw West Systems epoxy mentioned somewhere ... and would just like confirmation as to whether that was the best to use. If so, is 105 the resin to use ... and then which hardener ... 205 Fast, 206 Slow, 207 or 209? When you join two formers ... the matt that is wrapped around the centre ... is that normal fibreglass matt? Thanks, Roger Cheers, Roger |

||||

| BenandAmber Guru Joined: 16/02/2019 Location: United StatesPosts: 961 |

I use automotive clear fiberglass resin with the hardener that comes with it I also use fiberglass cloth along with it I paid around 60 bucks for a gallon of it  I used it to epoxy Transformer core's together I also use it over the wires on every layer The chokes and Transformers I have made are completely silent Although this has worked graet for me I would recommend you research it before you use it I don't know the lifespan of the product and life expectancy with the heat of a transformer I had already bought this for another project and had it on hand so I used it I also used it after I epoxyed magnets on a rotor of a 3-phase motor I would definitely recommend using the fiber glass cloth with it it gives it a lot more strength be warned i am good parrot but Dumber than a box of rocks |

||||

| BenandAmber Guru Joined: 16/02/2019 Location: United StatesPosts: 961 |

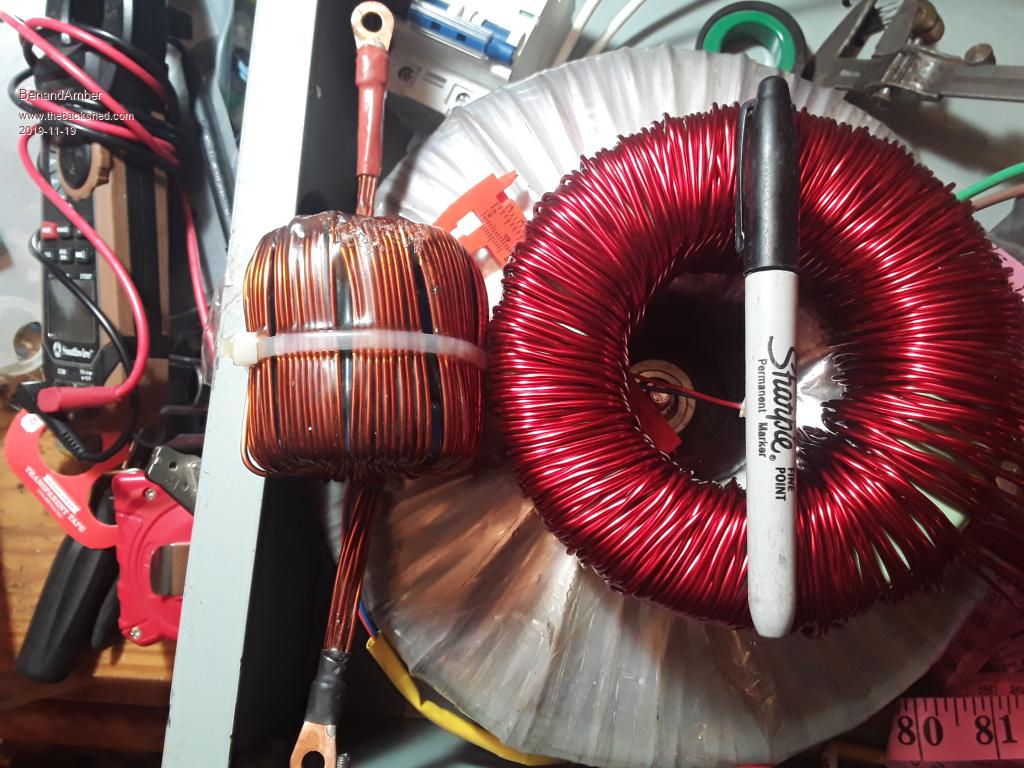

I epoxyed both of these chokes with this type of resin Both are completely silent The smaller one on the left shows you what they look like after being epoxied The larger one on the right got epoxy before I used it in my big inverter I do not use the fiberglass cloth when coating the wires Only when bonding things together Edited 2019-11-19 03:13 by BenandAmber be warned i am good parrot but Dumber than a box of rocks |

||||

renewableMark Guru Joined: 09/12/2017 Location: AustraliaPosts: 1678 |

I'm the only one that does it, but I use polyurethane. Here Pic The finished torroid holds onto more heat. The heat does dissipate when it gets hot but not as well as epoxy. At the top end of the scale, it doesn't seem to get any hotter than an epoxied torroid, but at the lower end it seems to hold onto residual heat. So on a cold night of 6c it will still hold 14-16c. On a hot day of say 35c with it being worked hard with air cons going it may be 45-50c. I think 52c is the hottest I've seen it at the end of a hot day (with two previous 35c+ days), so it doesn't just keep accumulating heat. I use this for the insulation and shock absorbing properties it has. One thing about epoxy, is that it's very easy to dislodge it from a shiny surface. That's what enamelled wire is, and it's buzzing too, so I just prefer something that can flex. Stick some epoxy on a plastic scraper, or something else smooth and see how easy it is to flick off. The minimal paint on way Oz had in his instructions is very different to how manufacturers epoxy transformers. There is probably a good reason not to do it my way, but it's worked just fine so far. . Cheers Caveman Mark Off grid eastern Melb |

||||

| BenandAmber Guru Joined: 16/02/2019 Location: United StatesPosts: 961 |

I seen the pictures of yours Mark and I like the way you do yours I just had this Automotive fiberglass resin already around so I used it be warned i am good parrot but Dumber than a box of rocks |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 951 |

Thanks for your input BenandAmber ... very helpful ... and great photos too. I think I've been a bit concerned about both heat ... and potential insulation properties ... so I didn't want to go out and buy the wrong stuff. That could create a nightmare of having to unwind and rewind a torroid ... and potentially have to find more wire too ... no thanks.  Thanks Mark. I had seen yours and certainly appreciate that if it wasn't for perhaps issues with heat ... the polyurethane would be ideal. Should be a good insulator ... and having some body which is also flexible, should also be perhaps better than epoxy. Having said that ... I understand the importance of using the bare minimum to further insulate the wires and prevent vibration which could lead to shorted turns and noise nuisance ... but the most important perhaps is so we leave enough room for the needed turns. I've used plenty of fibreglass resin in the past to pot electronics ... but it can certainly be affected by heat ... and it also shrinks noticeably. I've also used gallons and gallons of winding insulating varnish too ... but that doesn't have much body ... so while it is ideal for its insulating properties, I can't see it holding the wires in place (during the winding stage) ... especially the way the torroids are wound with the spacing between turns. What has everyone else used? Cheers, Roger Cheers, Roger |

||||

renewableMark Guru Joined: 09/12/2017 Location: AustraliaPosts: 1678 |

Can't remember but someone said the torroid and it's mylar is ok up to 80c or so. Therefore considering my max temp ever seen of 52c isn't anything to worry about. 32c ambient outside right now, have one A/C going and the torroid is at 32c. Cheers Caveman Mark Off grid eastern Melb |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 951 |

Yeah ... I'm just looking for excuses to over think it. Haha! I ordered some epoxy off ebay with the slow hardener, so will see how it pans out. $64 for 1.2 litres delivered. It's certainly handy having all those temperatures referenced ... gives an idea of what to expect ... some assurance that things are going well. Cheers, Roger Cheers, Roger |

||||

renewableMark Guru Joined: 09/12/2017 Location: AustraliaPosts: 1678 |

I don't blame you for not going the polyurethane way. It's hard to stray from the well worn path, I seem to have an adventurous carefree streak. Anyway, since you have gone epoxy don't be a miser with it, goop it on enough to properly coat the windings well. Depending on how you plan to wind the torroid there will be plenty of room, so don't stress about overdoing the epoxy, goop it on properly. I will also advise to buy new mylar, using the second hand crap is just a waste of time, for $20 a roll you can buy nice new stuff that is a bit wider too. A bloke local to you in Adelaide sells it too. Have you actually decided on what system you are going with yet? Cheers Caveman Mark Off grid eastern Melb |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 951 |

It's hard to stray from the well worn path, I seem to have an adventurous carefree streak. Anyway, since you have gone epoxy don't be a miser with it, goop it on enough to properly coat the windings well. Depending on how you plan to wind the torroid there will be plenty of room, so don't stress about overdoing the epoxy, goop it on properly. I will also advise to buy new mylar, using the second hand crap is just a waste of time, for $20 a roll you can buy nice new stuff that is a bit wider too. A bloke local to you in Adelaide sells it too. Have you actually decided on what system you are going with yet? I do have a bad habit of straying from the path ... so I want to stay on it as long as I can.  My cores are from a 3kW AeroSharp and already have the 100mm centres ... so that should give me enough room without having to fight too much to fit everything in ... but I appreciate that too much epoxy will potentially cause the whole assembly to retain more heat than it needs ... so I guess it still is a bit of a balancing act. Having said that ... if yours can handle the heat with all the polyurethane ... then thicker epoxy should be ok as well. Since we're speaking about torroid heat ... I've been surprised that everyone fits a cap on top of the torroid as part of the mounting arrangement ... as that must retain a lot of heat in the core. Even if the cap (and base) had holes in them to allow more air through ... that would have to be easier on the torroid. See ... already looking off the path!!! I had looked online for new mylar but most I could find was adhesive ... so I'm pleased to hear there should be some available in Adelaide. Any ideas on contact details? The outer layers I took off were pretty messy ... but the inner layers look like new. I used a hot air gun on it every 10 foot or so while unwinding it ... and it shrinks back into shape amazingly. If I can't get some new stuff easily ... I'm not afraid to reuse this. The same can't be said for the wire ... that still bothers me a bit. I really should just buy a roll of 1.8mm and be done with it. Use the old stuff to make up the multicore primary windings perhaps. Hate to have to wind it twice.  I haven't decided 100% exactly what system I am going to build. I did receive Clockman's book and set of boards today actually ... but as I didn't hear back when I first enquired ... I also ordered some sets from Madness. Covering all bases! Once I've finished reading the book I'll decide which way to go ... and probably like all you guys, end up building a couple.  For a while there, I was contemplating getting a new, standard, everyday 6.6kW array and 5kW GTI ... just for the cheapness of the panels and being new and all ... then when you suggested getting a hybrid inverter as well ... then the price kept going up ... ... so now I'm swaying back to just building a 6kW inverter for my minigrid and adding another GTI to help with the workload and keeping the batteries topped up. I think what did it was seeing some cheaper panel sets available for sale locally. eg a 5kW array with a 5kW SMA GTI for $1,000. I possibly won't be able to use the 5kW GTI ... I understand I'll need to use 2 or 3kW GTI's to add to my minigrid ... but either way ... it's a lot cheaper than the alternative. Cheers, Roger Cheers, Roger |

||||

| BenandAmber Guru Joined: 16/02/2019 Location: United StatesPosts: 961 |

Seen this online thought it was a good idea By the way after you fiberglass resin a Transformer I wouldn't think there would be any hope of getting it back apart I honestly think you would be lucky to save the core I haven't noticed any shrinking problems the one inverter has been running continuously for quite a few months now But who knows a very legit concern be warned i am good parrot but Dumber than a box of rocks |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 951 |

Seen this online thought it was a good idea By the way after you fiberglass resin a Transformer I wouldn't think there would be any hope of getting it back apart I honestly think you would be lucky to save the core I haven't noticed any shrinking problems the one inverter has been running continuously for quite a few months now But who knows a very legit concern Thanks BenandAmber. The star shaped washer is what I had in mind ... 3 or 4 fingers ... and cut the metal disc much the same. Will allow at least a bit more air through. And then address the bottom in a similar fashion so can get some flow through. Will add more height to the assembly, but would be interesting to see how it compares temperature wise. Regarding rewinding an already epoxied transformer ... I agree ... I think I'd cut my losses, hacksaw through the windings and start again.  When I used fibreglass resin to pot electronics, it was only about the size of a matchbox ... but the shrinkage was significant ... especially if I added more catalyst than I was supposed to! Having said that, with the amounts being used in the torroids, I wouldn't expect any issue at all ... besides I bet you're not the only one to have used it for this purpose and you all seem to have fared ok. Cheers, Roger Cheers, Roger |

||||

renewableMark Guru Joined: 09/12/2017 Location: AustraliaPosts: 1678 |

I had looked online for new mylar but most I could find was adhesive ... so I'm pleased to hear there should be some available in Adelaide. Any ideas on contact details? Cheers, Roger It's in my build thread here This might be of interest to some too. Cheers Caveman Mark Off grid eastern Melb |

||||

renewableMark Guru Joined: 09/12/2017 Location: AustraliaPosts: 1678 |

Oh yeah just to follow up with some more temp readings. Recently we had two hot days in Melb, the second one was 38c or 100f. The poly coated torroid got to 41c after a day running 2x AC units. So it didn't get much hotter than ambient. When the cool front came through it was 20c and the torroid took till next morning to loose it's temp and get down to that level. So yeah, it holds onto heat, but doesn't seem to get much higher than ambient with enough air flow. Two of those poly tubes will do a double stacked torroid @ $28 and it's easy to use, no mixing, just goop it on and spread it around with your hand using a rubber glove. If anyone tries it, don't wear a nice shirt while doing it as it's impossible to get it out..... have a guess how I know  Cheers Caveman Mark Off grid eastern Melb |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 951 |

I had looked online for new mylar but most I could find was adhesive ... so I'm pleased to hear there should be some available in Adelaide. Any ideas on contact details? Cheers, Roger It's in my build thread here This might be of interest to some too. Thanks again Mark. I spoke to John there yesterday to price some wire and he's ringing back on Monday. I'll ask him about it then. He actually used to work for OH OBriens who I used to get copper wire from 40 years ago. Recently we had two hot days in Melb, the second one was 38c or 100f. The poly coated torroid got to 41c after a day running 2x AC units. So it didn't get much hotter than ambient. When the cool front came through it was 20c and the torroid took till next morning to loose it's temp and get down to that level. So yeah, it holds onto heat, but doesn't seem to get much higher than ambient with enough air flow. Two of those poly tubes will do a double stacked torroid @ $28 and it's easy to use, no mixing, just goop it on and spread it around with your hand using a rubber glove. If anyone tries it, don't wear a nice shirt while doing it as it's impossible to get it out..... have a guess how I know  Those are very respectable readings considering the temp for the day ... barely above ambient. Be interesting to compare how quickly a torroid with epoxy cools down ... but can see yours is quite happy. The epoxy turned up yesterday as well. Ebay said it would only be here next Tues or so ... but it came from Pt Adelaide ... so really quick. One litre of epoxy and 200ml of hardener ... $63 delivered. I use a reasonable amount of silicone and various conformal coatings for work ... and I know what you're talking about when it comes to clothing. For me, it's my strides ... they end up with all sorts of suspicious looking marks all over them ... especially if they are new. Happens every time.  Cheers, Roger |

||||

| Murphy's friend Guru Joined: 04/10/2019 Location: AustraliaPosts: 673 |

The epoxy turned up yesterday as well. Ebay said it would only be here next Tues or so ... but it came from Pt Adelaide ... so really quick. One litre of epoxy and 200ml of hardener ... $63 delivered. 5:1 mix epoxy is a little more difficult to measure out in small quantities than the 2:1 mix I use. I use a little electronic gram scale and those plastic pill bottles with the top cut off to mix it in. Very small quantities can then be made up. I know, its supposed to be measured by volume but for smaller quantities weighing worked fine for me. A tip, if you are using epoxy in Winter keep the containers warm. Another tip, I use those little brushes that come in a 3 pack at Bunnings, they can be rinsed in acetone for another one or two uses but eventually go hard enough to be only good to bin. Lastly, try to keep that stuff of your skin, some people easily get sensitised and after that they cannot get near it again. Use rubber gloves. |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 951 |

The epoxy turned up yesterday as well. Ebay said it would only be here next Tues or so ... but it came from Pt Adelaide ... so really quick. One litre of epoxy and 200ml of hardener ... $63 delivered. 5:1 mix epoxy is a little more difficult to measure out in small quantities than the 2:1 mix I use. I use a little electronic gram scale and those plastic pill bottles with the top cut off to mix it in. Very small quantities can then be made up. I know, its supposed to be measured by volume but for smaller quantities weighing worked fine for me. A tip, if you are using epoxy in Winter keep the containers warm. Another tip, I use those little brushes that come in a 3 pack at Bunnings, they can be rinsed in acetone for another one or two uses but eventually go hard enough to be only good to bin. Lastly, try to keep that stuff of your skin, some people easily get sensitised and after that they cannot get near it again. Use rubber gloves. Thanks Murph. I was surprised to read on the containers that it could be measured either by volume or by weight ... so I reckon I should be ok. I use acetone for lots of things, so that will be handy if I can get a couple uses out of my brushes. In fact, I have some smallish antistatic type brushes that are quite stiff and wash out well with acetone, so I might give them a go. As long as I don't forget to wash it in time!! Gloves do sound like a good idea, yep. Cheers, Roger Cheers, Roger |

||||

| BenandAmber Guru Joined: 16/02/2019 Location: United StatesPosts: 961 |

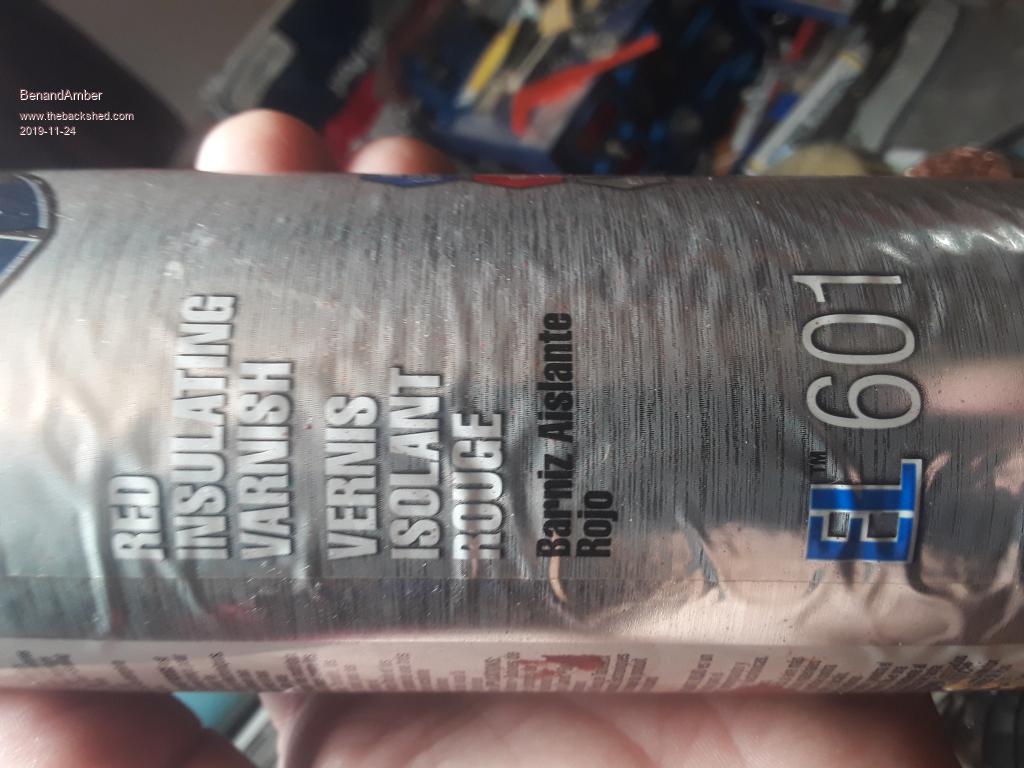

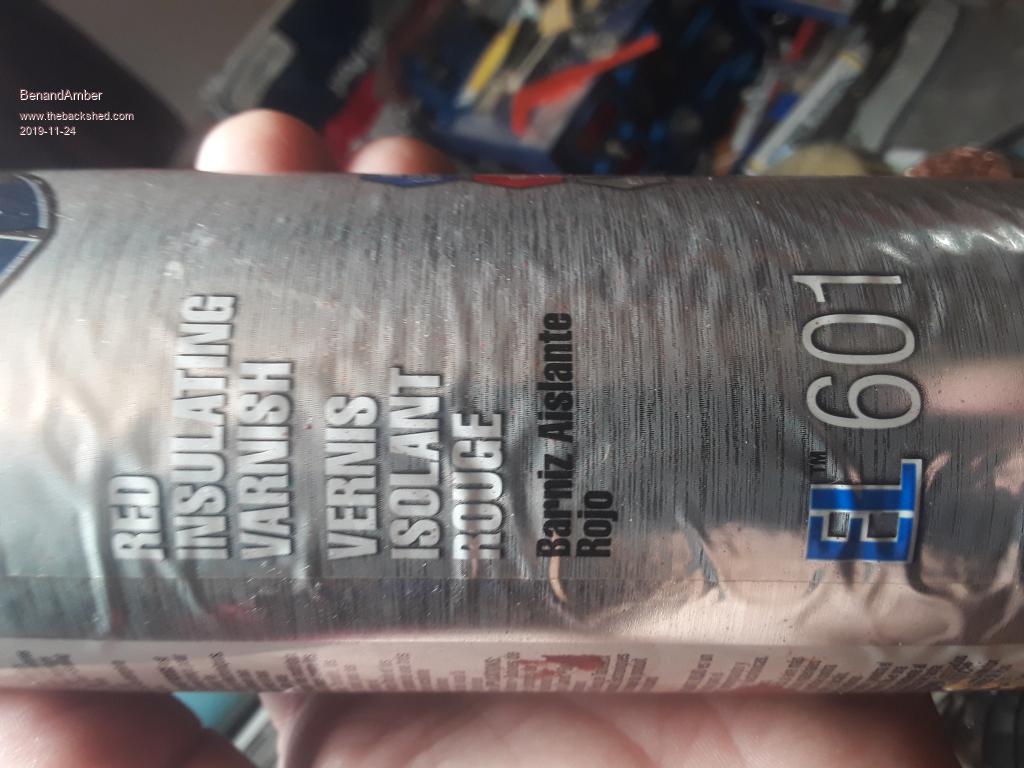

New enamel wire is very expensive if there's any way possible to save your old that's the best route to go You can buy spray cans of the Transformer wire enamel you can respray your own wire before you use it I have one Transformer here that I used uncoated wire sprayed it with the Transformer wire enamel spray then as I wrapped it brushed on the fiberglass resin I honestly think it will last as long as I do  be warned i am good parrot but Dumber than a box of rocks |

||||

renewableMark Guru Joined: 09/12/2017 Location: AustraliaPosts: 1678 |

............ Be interesting to compare how quickly a torroid with epoxy cools down ... Yeah, but I suppose it doesn't really matter, it's just not good to have the maximum temp get too high, once it heats up, it appears to let it go fairly well. I actually got this idea from a silicone oven mit. When you pick up a hot baking tray it doesn't get your hand hot for a little while, but when it does heat up, that heat gets transferred through the mit very well. Once hot, it's useless, the heat just goes right through it and burns your hand. So making the torroid essentially a big lump with all the voids filled in with polyurethane that whole area transfers the heat. Once hot, that heat appears to dissipate just fine, just like going through an oven mit, but yeah, it needs good air flow. Cheers Caveman Mark Off grid eastern Melb |

||||

| Murphy's friend Guru Joined: 04/10/2019 Location: AustraliaPosts: 673 |

if there's any way possible to save your old that's the best route to go You can buy spray cans of the Transformer wire enamel you can respray your own wire before you use it I have one Transformer here that I used uncoated wire sprayed it with the Transformer wire enamel spray then as I wrapped it brushed on the fiberglass resin I honestly think it will last as long as I do  One sees lots of good ideas here but, unfortunately, also bad ideas. The above post comes into the bad idea category IMO. I have seen how the wire makers apply the enamel to the copper wire in a factory and, believe me, there is not a man standing next to a big spool of copper wire with a can of that above spray in his hand. Instead, its a complicated arrangement of enamel baths and drying ovens where the wire passes through from its bare copper stage to be fully enameled. The above mentioned spray is intended to repair scratches on copper wire that is *already wound in place* It is *not* tough enough to withstand the mechanical stresses applied when winding the wire around a former or core. Using that product to repair damaged wire, strung between trees as suggested in an earlier post, is very like using a can of spray on rubber to repair the thread on worn tires. If you want to play Russian roulette - its your choice - but think about the consequences before recommending something quite unsuitable here. |

||||

| Page 1 of 2 |

|||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2026 |