|

|

Forum Index : Electronics : 6Kw Ozinverter build

| Page 1 of 51 |

|||||

| Author | Message | ||||

renewableMark Guru Joined: 09/12/2017 Location: AustraliaPosts: 1678 |

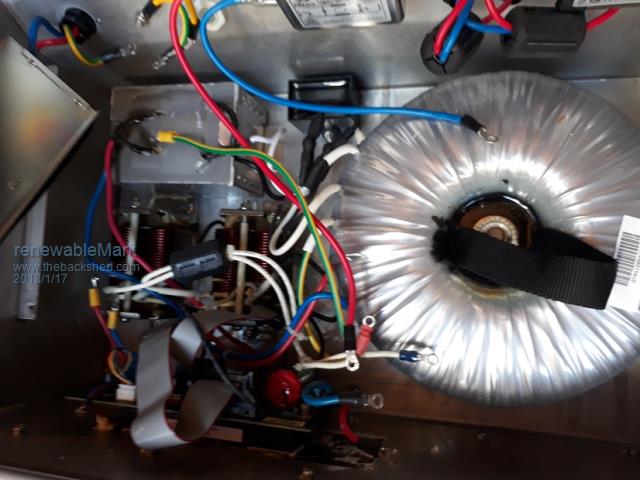

Hi guys, I'm doing a pretty standard Ozinverter build, not looking to do any mods and get into strife, just a copy of Oz's great work. First of all was to unwind the torroids from the 2 3Kw aero sharps I have. So far have 1 unwound and had some issues straitening the wire, so I came up with this from some old parts lying around.  Seems to work pretty well and is run by a frequency inverter so it can be slowed down to a manageable level. The second aero sharp I opened up looked different inside, one had one of the small transformers potted up with grey epoxy and the torroid had a cloth strap attached to it. The date was only a month apart from the other one that appears to be different.   So I'll unwind the second one and hopefully it's the same size. Most parts for the control board are on order, I really need some peace and quiet to order the rest of them, with so much noise it's impossible to type out numbers and search for parts online. Small house means lower bills, but no where to get some peace. I'll get there. Cheers Caveman Mark Off grid eastern Melb |

||||

renewableMark Guru Joined: 09/12/2017 Location: AustraliaPosts: 1678 |

Thanks Madness for the tip on removing the torroid it worked a treat. Simply cut away all attached wires, turn the unit upside down, lift the heavy end 45deg and drop it and it will fall out. The only thing I would add is to have a foam matt for it to fall onto. Cheers Caveman Mark Off grid eastern Melb |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

I would avoid winding on that small spool as each time the wire bends it gets stiffer, that is one step you can avoid. I use push bike rim and roll it on to it as I pull the wire through the bearings. Then it comes off the bike rim very easily and you store it in neat coils. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

I now just stretch the wire after attaching it to the car tow ball..... pull it very tight until the bends disappear and done. Seems to be less work hardening. Any micro cracks in the enamel will be fixed with the epoxy. ........oztules Village idiot...or... just another hack out of his depth |

||||

renewableMark Guru Joined: 09/12/2017 Location: AustraliaPosts: 1678 |

Bugger, I was quite happy with my straightener   Cheers Caveman Mark Off grid eastern Melb |

||||

renewableMark Guru Joined: 09/12/2017 Location: AustraliaPosts: 1678 |

Do you actually drive the car to get it super tight or just pull on it by hand? Cheers Caveman Mark Off grid eastern Melb |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

I can imaging Oztules fish tailing all over the place with the wheels spinning to get all the bends out.     There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

renewableMark Guru Joined: 09/12/2017 Location: AustraliaPosts: 1678 |

In a datsun 120y? Cheers Caveman Mark Off grid eastern Melb |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

He would be in this  From here. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

I do it that way too. Secure one end in my workshop vice and run the length of wire right down the driveway sometimes right into the street. With about fifty feet of wire, it can be stretched quite easily about an extra foot. The wrinkles come right out. Every time you bend that copper it further work hardens, and you get into deeper and deeper poo. Going back and forth around a bunch of pulleys may not be such a good idea. It will certainly straighten out the wrinkles, but it is also going to stiffen up the wire. I really like the bike rim idea for the same reason. Cheers, Tony. |

||||

renewableMark Guru Joined: 09/12/2017 Location: AustraliaPosts: 1678 |

Ok dumb question, why does it matter if it gets harder? Still should be easy enough to get wound around the toroid. Reckon ill do the stretch method though, sounds easier and faster too. Cheers Caveman Mark Off grid eastern Melb |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

If the wire goes really hard on you, it ends up as lumpy crooked ugly winding. Thats bad enough on one single layer. Try to wind another layer over the top of that, and you are really in for some fun. Cheers, Tony. |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

The stiffer it is the harder it is to wind, you will know what I am talking about once you get into the winding stage. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Yes indeed !!! Cheers, Tony. |

||||

renewableMark Guru Joined: 09/12/2017 Location: AustraliaPosts: 1678 |

OK stretch it is, low range 4x4 and streeeeeeeeeeeeeetch. Cheers Caveman Mark Off grid eastern Melb |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Just a pair of vise grips and a bit of heave will be all that is needed. About half the stretch will be all the wrinkles coming out. You can actually feel it stretch, and it does not spring back. It will end up dead straight and look brand new. Try cutting off a 100mm length. Bend it once to judge how stiff it is. Bend it three or four more times in the exact same spot and note the difference. You might be surprised how quickly nice friendly wire can turn into a real bastard. Cheers, Tony. |

||||

renewableMark Guru Joined: 09/12/2017 Location: AustraliaPosts: 1678 |

Ohhhh phuk that's a good demo. Makes a big difference. Keep the pointers coming fellas. Cheers Caveman Mark Off grid eastern Melb |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

The less that wire is handled, the easier the winding job will be. Every time it is bent it gets meaner and nastier. Cheers, Tony. |

||||

renewableMark Guru Joined: 09/12/2017 Location: AustraliaPosts: 1678 |

Finally got the second one unwound. Thankfully both are exactly the same size.  Cheers Caveman Mark Off grid eastern Melb |

||||

Madness Guru Joined: 08/10/2011 Location: AustraliaPosts: 2498 |

That brings back memories, haven't seen a naked core in a long time. There are only 10 types of people in the world: those who understand binary, and those who don't. |

||||

| Page 1 of 51 |

|||||