|

|

Forum Index : Electronics : Wiseguy New Inverter Build Nano R6

| Author | Message | ||||

| nickskethisniks Guru Joined: 17/10/2017 Location: BelgiumPosts: 462 |

I think that will work Mike. Another approach, when the problem is caused by spiking, what about adding an L(C)filter on the 5V rail? |

||||

| -dex- Senior Member Joined: 11/01/2024 Location: PolandPosts: 101 |

Mike, Your solution is fine, but I don't like that I now have to operate two switches instead of one. Maybe you like my anotother aproach to solve the problem. I'm referring to the original diagram now, not the last modification: Leave everything as it was, replace the on/off switch with DPDT. Use the second pole of the switch to discharge the 12V/5V caps in the off position. |

||||

| wiseguy Guru Joined: 21/06/2018 Location: AustraliaPosts: 1206 |

Dex I am afraid that what looks like a simple solution to you, I cannot see how it will work in practice without causing other issues. I suggest you try to actually come up with a schematic to do this and you may then see the problem. Maybe I might then have a better understanding of your suggestion and why it might or could work. The elegant way the inverter switched on and off from a single switch took a lot of planning and understanding of the inner workings of the Nano code. You know I don't have the energy or time right now to explain why someones simple sounding suggestion of how the issue might be fixed when I'm not sure they fully understand all the balls in motion and why the contactor stays in after the existing switch is turned off until after the SPWM has ramped back to zero and then the contactor opens. If you short the 5V line to ground whilst the inverter is running and full current is flowing I cant see any solution that does not undo that basic function and protection and there are a lot of FETs to replace if they dont take well to a crowbar on the logic supply. Why is the second switch such an issue? If you want to stop the inverter set the run/stop switch to stop. If you want to turn off the inverter after it is stopped turn the on off switch to off. if you want a simple start to the inverter turn the run stop switch to run and then turn the on off switch to on. Or leave the run/stop switch in the stop position and after turning the inverter on then switch it to run. The only nono is to set the on/off switch to off before stopping the inverter first, put an ejector switch with red cover over the on off switch. I have devoted an enormous amount of all my spare time to get to this point since I sent your boards to you in February? I am now being relied on to provide a solution to this 11th hour glitch that will work. You see before I came to the forum no one used just an on off switch, they had a push button pre-charge and then when they guessed the caps were charged they threw the main switch to either a bang or then operated a run switch to either a bang or welcome hum. When I first suggested the solenoid solution I was bagged endlessly but in my usual fashion I ignored the "help" and criticism and went ahead and proved it could work well, then some others slowly adopted it. This is not the end story just the end of a chapter. I have a need to provide a working solution to all the members that want to build this type of inverter and have reliable power and have placed their trust and faith and money in a Wiseguy solution. At some point in all projects you need to stop farting about and draw a line at an acceptable solution that works and then breathe a bit and start thinking about the next chapter otherwise it will never end. I can assure you my brain cells are already forming a plan of how to make much better single switch solution for Rev8 and it will benefit from all that we have learned from this episode. I am prepared to help you maybe have a single switch solution but I have racked my brain and as the solution got more and more complicated I gave up and re thought out from first principles a working solution for the Rev7 everyone is about to receive and applicable to the Rev6 you have and is (I hope) compatible with existing software - I cant see any gotchas yet. I am also still churning over ideas for a single switch solution before the boards are returned to me and shipped out, but at least now I do have a fall back solution with 2 switches that I am sure will work fine in the absence of a single switch and is relatively easy to implement. Edited 2024-06-07 00:35 by wiseguy If at first you dont succeed, I suggest you avoid sky diving.... Cheers Mike |

||||

| wiseguy Guru Joined: 21/06/2018 Location: AustraliaPosts: 1206 |

After all the images and discussions of how to tame the switching regulators versus linear regulators to provide a fix NO it wont. I would like to present the reality of the amnesia problem and its cause. A very slow rise or fall of the 5V line will/can cause the LCD nano to corrupt its code and display amnesia. This was proved by me tonight by using a 5V linear adjustable supply, directly coupled to the controllers 5V logic supply, no switching regulators operating. When the DC input was reduced from 5V with everything working fine, then reduced and slowly varied around the 2V mark down and then up slowly (10mV steps) just the once, the LCD Nano no longer worked with out reprogramming. The pulsing seen on the switching regulators is probably exacerbating the issue but it will do it with a dead smooth DC level. It is the Nano that is badly behaved with a low supply voltage so I will investigate further the Nano's brown out detection or and addition of a 3 pin supply voltage reset monitor to try to see if the problem can be fixed at its actual source. Edited 2024-06-07 02:22 by wiseguy If at first you dont succeed, I suggest you avoid sky diving.... Cheers Mike |

||||

| wiseguy Guru Joined: 21/06/2018 Location: AustraliaPosts: 1206 |

Well there is more to the story of the LCD's failure to function. There are two different types of failure modes I have now found. In redoing the tests I did last night and early this morning I discovered the second failure state of the LCD display. With the slowly reducing voltage at around the critical threshold the LCD can just display the "black digit blocks" but from this point there are two scenarios. The first is that a power down and restart of the system causes the LCD to resume normal operation. The second more insidious failure is that a power recycle does not restore normal operation of the LCD requiring the code to be re-uploaded to it. At this point, to avoid a lot of reading feel free to skip to the Executive Summary. My forte is not in uC's (microcontrollers), their internals or for written code. I have been reluctant from the word go about the wisdom in using a uC for inverter operation. The problem is twofold, firstly the success or failure of the project is a direct reflection of the quality of the written code and the code writers knowledge about the uC strengths, weaknesses foibles and keeping up with the errata updates. I can solve hardware problems but I also have to rely on software & uC experts when the issues are under the hood of the uC. Secondly there are also hardware issues that can cause unexpected results in the uC and they can come from a variety of causes. I see the main issues as not being that using a uC is a bad thing, if they work as intended life is good, but I am releasing my control over a successful project outcome to other parties and I become reliant on them now if there are issues. I acknowledge that a hardware issue caused by me could drag their efforts down too. But when there are issues, finding the root cause and fully understanding the problem is paramount to solving it. So with the fault, what is cause what is effect and how do we reach into the internals of the uC to see what happened in the black box which no longer does its job. In the past I have used in circuit emulators and all sorts of similar tools to resolve issues, but at this stage of my life I am reluctant to try to solve the Nano problems because simply I am a bit out of my depth. I no longer have the tools the support or the will to solve these types of issues on my own. I can do a bit more testing using the pins available from the micro such as an external hardware reset that operates from 1.5V upwards and holds the Nano in reset until the 4.6 V or whatever the supervisors threshold for normal operation is. Maybe it can be solved with this but if not, we do not have a solution yet. (which solution for what problem??) I also read conflicting articles about EE code becoming faulty (corrupt) and its causes and there are many ways to do it from buffer overruns, stack overflows, power supplies that can wake a processor and cause unknown internal operation, as it never achieves the normal rail voltage so the BOR (brown out reset) is never triggered and throw into this imperfect code or understanding of the micro's internals and I am sure you can see the problem. I have been using and designing in microcontrollers since about 1987, but I often have worked in collaboration with other engineers along the path. I always have used specialist software engineers to write code, my abilities start to fall short after developing test code stubs to exercise ports and bits and encoders decoders etc. Yes we used to do that, now micros mop up a lot of that stuff internally. The last comment to make is that for the Wiseguy/Poida/controller/Inverter/LCD, only 50% in the field work. That is KeepIS and Dex, KeepIS has had no failures or issues to my understanding and yet Dex has. Ok to be fair Poida and I also have powered up the controllers and LCDs hundreds of times without a single failure or glitch where a Nano needed code to be reloaded. The dilemma I now face is am I fixing/chasing a problem that only one person has and maybe no one else will ever see it? Dex has made comments about the amount of electrical noise in his cabinet with all the MPPTs and inverter running. Is this interference also part of the problem ? Poida has worked hard to create robust reliable code, KeepIs has done the same extending on Poidas code to include features and performance that meets with his needs and expectations and LCD screen. My understanding is that KeepIS has uploaded a hex copy of the Inverter and LCD codes to the Nanos with no bootloader and then no amount of fiddling with power supplies has caused a code crash that needed new code to be uploaded, this is encouraging. Executive Summary So I have arrived at a conclusion and that is there will be no modifications to the inverter or LCD display hardware. I will recommend (ask) to Poida that his code is released as hex files to the forum (no bootloader) to be uploaded to the Nanos. This has two effects no one can reverse engineer the code and steal the IP within it and the bootloader cannot have the power to overwrite code space. KeepIS might also do the same with his code for anyone that wants to try something different. These are my thoughts and both or either might flatly refuse. I would also suggest that at Poidas discretion he may be (reluctantly?) prepared to release his listing if someone asks for it but that would be totally at their risk if they change anything. I did blow my FETs by going down this path once.  I will however continue to see if a voltage supervisor can easily be retrofitted to the Nano module - and only when it proves to stop the code amnesia. I will also try a linear 5V regulator instead of the switching unit to see how it performs - at this stage it could be the only component change I might recommend. I realise that these improvements to the onboard power supply might become redundant if the hex files minus bootloader fixes the susceptibility to the inverters decaying power supply. Closing comment yes I can induce errors to the display by purposely fiddling with the power source and trying to make things play up - and they do, but I have not experienced Dex's problems with the display during my normal operation. Sorry for the last few longish posts. Edited 2024-06-07 14:02 by wiseguy If at first you dont succeed, I suggest you avoid sky diving.... Cheers Mike |

||||

| -dex- Senior Member Joined: 11/01/2024 Location: PolandPosts: 101 |

Please ignore my earlier suggestion regarding the circuit, it was not well thought out, now I see how much of a rush - a bad advisor. Sorry, I didn't want to open a can of worms, so I described the problem in my thread and what I did about it, and there was no request for improvement there. Let other users test it, if minor corrections are needed, you are already ready for it. Mike, tonight was my first off-grid night. It's a great feeling! Much of this is due to you. Someone in a completely different part of the world built your inverter and is now texting you from a computer that is powered by the inverter of your design, isn't that great? Certainly, many other users will repeat this success, and minor problems will quickly solved   |

||||

| KeepIS Guru Joined: 13/10/2014 Location: AustraliaPosts: 1866 |

Bringing up the problem you encountered is what we need, as Mike said, You and I are likely the only ones who have built his complete inverter, thanks for trying our suggestions to the problem you encountered, your input has really made us go into it this even deeper.  NANO Inverter: Full download - Only Hex Ver 8.1Ks |

||||

| wiseguy Guru Joined: 21/06/2018 Location: AustraliaPosts: 1206 |

Great news Dex I am very happy to hear that you are finally off grid. Thanks for having the confidence in the design and to take it on. What value chokes did you finalise on in your build? When you said the LCD was crashing regularly then I began the hunt for the reason. But in the interim working with KeepIS you found a solution with a hex upload minus bootloader. I came to the conclusion today that I do not want to make hardware modifications until I am sure there is no other option. What is the most power you have put through the inverter to date ? Well done !!  If at first you dont succeed, I suggest you avoid sky diving.... Cheers Mike |

||||

| -dex- Senior Member Joined: 11/01/2024 Location: PolandPosts: 101 |

2x30uH. The chokes are probably the weakest part in the system at the moment, so I'm very careful with loading. They have a small copper cross-section, which means they heat up quite quickly and hot. I installed a temperature sensor and connected it instead of a toroid temperature sensor. It means, on lcd in Tor section, in fact I see choke temp. |

||||

| wiseguy Guru Joined: 21/06/2018 Location: AustraliaPosts: 1206 |

Looks like Morgs67 & Poida wins the prize - thanks fellas I just had to get to the answer my way by a process of elimination. The curly part was the noise of the 5V regulator that was posted and it looked terrible combined with the fact that I was seeing activity on the USBtx data LED I wanted to see if it was the USB IC outputting crap or the processor. The reset for the USB IC is via a capacitor from the Nano uC so putting a reset device on the Nano uC does not preclude the USB IC from still outputting crap (if it was the culprit) I do know voltage supervisors well having first used them over 35 years ago. The voltage monitor did fix it though and only 1 is required for the Nano on the controller. The only TO92 supervisor part I had in stock is an S8054HN an old Seiko part with open drain reset, active low and around 4V trip point. I put one on the Nano and fully tested the voltages from 0V - 5V and everything is as dead as a dodo until greater than ~ 4.1V where it comes to life and no amount of slow twiddling between 1 & 2.5V resulted in any LED activity. Return to 5V all working fine. So stomping on the data line in reset stopped crap from upsetting the LCD Nano. A really lucky outcome is that the part can be mounted under the PCB and a 1-1 connection for 3 pins on the nano socket solder side so very easy to retrofit and putting it on the main PCB then 1 part is not required to be fitted to each nano module. The only bad news is the part is ~ $1.20 from Digikey there may be cheaper sources ie Farnell and really any part with threshold voltage from 3.5V - 4.3V would all be fine. I prefer open drain but there are open collector parts with very low power consumption that should be fine also. I would recommend the S-80838CNY-B2-U which has a threshold of 3.8V and is closest to the tested S8054, but there are other similar choices. The Nano on the controller that crashed last night when playing with low voltage around the 2V threshold appears to be badly bricked. It refused to program, the message was something like "cant find serial port or no device inserted". I tried reinstating a new bootloader but it wont have a bar of that either. If I request device ID it responds as usual with the same answer as a good one but apart from that its broken. Any ideas what went wrong or how to fix it? I suspect a random fuse burnt unintentionally but which one and how to clear it - its not the $3 cost but I am sure its a simple fix and curious what caused it. Edited 2024-06-08 01:32 by wiseguy If at first you dont succeed, I suggest you avoid sky diving.... Cheers Mike |

||||

| KeepIS Guru Joined: 13/10/2014 Location: AustraliaPosts: 1866 |

Just need the little Programmer, then you can flash the bootloader if you want, or just the program in the IDE screen, as you normally do, or the compiled Hex version that the IDE spits out. NANO Inverter: Full download - Only Hex Ver 8.1Ks |

||||

| phil99 Guru Joined: 11/02/2018 Location: AustraliaPosts: 2584 |

If you don't have the programmer there are instructions for using another Nano or Uno as the programmer to load the bootloader. |

||||

| KeepIS Guru Joined: 13/10/2014 Location: AustraliaPosts: 1866 |

To add to that, the host burner program (code) and the boot loader (code) are supplied as part of the Arduino IDE. BTW even with a voltage supervisor IC, I would not use that problem 5v regulator. . NANO Inverter: Full download - Only Hex Ver 8.1Ks |

||||

| wiseguy Guru Joined: 21/06/2018 Location: AustraliaPosts: 1206 |

I used a uno to attempt to burn the bootloader - I have done it successfully many times. The Nano last night though refused to cooperate and I refuse to believe there is an electrical breakdown at ~ 1.5 - 2V that is why I am going for the fuse that got corrupted maybe it asks for an external clock now or similar shoot yourself in the foot issue. But I dont know what fuses I should be looking at or how to unset or set as the case may be. KeepIS I bought the programmer and header and used it for bootloader reinstatement but it had issues too. I am 100% sure it was not a static damage issue I am too careful for that to happen. I gave up and built another Nano to complete my tests with the rail supervisor. If at first you dont succeed, I suggest you avoid sky diving.... Cheers Mike |

||||

| KeepIS Guru Joined: 13/10/2014 Location: AustraliaPosts: 1866 |

Yes I totally agree with you - very unlikely. Try this program Program It has the options you need to look/set fuse settings. But of course not if you cant read it. I noticed a youtube video on repairing the common issues with the Nano series if you think there is a HW problem, I never looked at it, but I often see in the search list EDIT: Forgot to add the program just unzips and does not install - stand alone app. . Edited 2024-06-08 11:04 by KeepIS NANO Inverter: Full download - Only Hex Ver 8.1Ks |

||||

| wiseguy Guru Joined: 21/06/2018 Location: AustraliaPosts: 1206 |

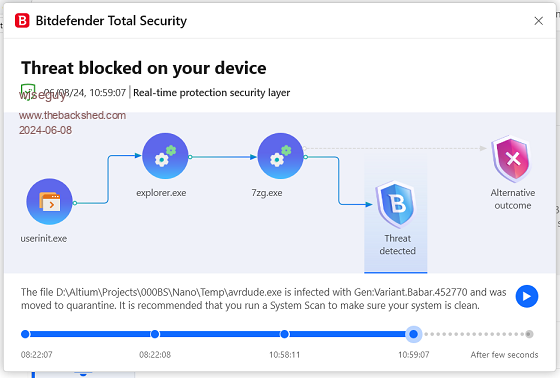

I finally figured out the real program name and downloaded and installed it. The first message I got was from Bitdefender the screen shot is below.  I don't really fee comfortable to continue with it, what is your opinion ? Edited 2024-06-08 11:36 by wiseguy If at first you dont succeed, I suggest you avoid sky diving.... Cheers Mike |

||||

| KeepIS Guru Joined: 13/10/2014 Location: AustraliaPosts: 1866 |

This is the correct github address - Bitdefender and others are know for false reporting. AVRDUDESS Click on big GREEN code button and download ZIP - no problems here and I just downloaded it. . NANO Inverter: Full download - Only Hex Ver 8.1Ks |

||||

| wiseguy Guru Joined: 21/06/2018 Location: AustraliaPosts: 1206 |

This is like days of our lives with this damn Nano low voltage issue. I spent more time today running slow changes in the rail voltage between 1.5V & 2.5V to be sure to be sure.... and would you believe I saw no flash of the Inverter Nano TX LED but as I restored the rail to 5V I had black blocks on the display Nano, Cycling the power off and on & pressing the LCD Nano reset did zilch so I would recommend a 5V rail supervisor is placed on the LCD Nano as well. If/when we go to Rev8 perhaps we should have a 4 wire connector between the controller card and the LCD Nano. Then they can share the 5V rail supervisor on the main controller card and the 4th wire carries the reset line to the LCD Nano's reset pin. Cable difference in cost between 3 wires and 4 wires is a few cents, much cheaper than rail supervisors from Digikey. By the way LCSC has some 4.2V supply monitors AZ7042Z-E1 for under 9c each. I have emailed and asked LCSC to expedite 250 - 500 HY5608s as they will be needed anytime soon. If at first you dont succeed, I suggest you avoid sky diving.... Cheers Mike |

||||

| KeepIS Guru Joined: 13/10/2014 Location: AustraliaPosts: 1866 |

Mike I'm wondering if in the next rev, the LCD might have its own regulator, and power it from 12v, help keep the 5V nano rail clean, just a thought I had the other day, I intend to try it - even though I have not been able to replicate any of this on mine, I just want to reduce any Solar reg and inverter switching noise out of the 5v line, Electronics is fickle, Murphy must have lost my address! . Edited 2024-06-08 20:43 by KeepIS NANO Inverter: Full download - Only Hex Ver 8.1Ks |

||||

| wiseguy Guru Joined: 21/06/2018 Location: AustraliaPosts: 1206 |

I think that both Nanos should use the 12V supply option. I also think they should both be controlled by a common or separate 5V supply supervisor, The little switchmode or a 7805 regulator could power the LCDs 5V not to be confused with the LCD Nanos 5V being derived from 12V. I just saw the specs for the Nanos on board regulator and they are saying it can supply 800mA (not sure if the solder is solid at this value....) but for the LCD backlight I think it only needed about 50mA so I suspect a Nano fed from 12V can drive the LCD without a separate regulator its only around 0.35W - to be confirmed next time I am in the workshop. I am also considering in Rev8 using a true RMS IC for the AC volts and Amps so things like the AC relay can make a disconnect decision accurately. I not sure I want the Nano to crunch numbers to get the true RMS values - I'll ask for guidance here. In the past True RMS converters were not cheap not sure if that has changed of late, will look into it. The Boards are finished from JLPCB finally - the capacitor boards were at 67% complete & were sitting in QC for 2.5 Days like that, after everything else was finished. They would not tell me anything about why but I suspect they had to re-run them. Anyway should be picked up tomorrow & heading back here. Edited 2024-06-08 21:48 by wiseguy If at first you dont succeed, I suggest you avoid sky diving.... Cheers Mike |

||||

| The Back Shed's forum code is written, and hosted, in Australia. | © JAQ Software 2025 |