|

|

Forum Index : Electronics : Time for a new Warpinverter build

| Author | Message | ||||

| Haxby Guru Joined: 07/07/2008 Location: AustraliaPosts: 420 |

Ah I didn't know that there were different versions of the transformer within the same power rating. That's annoying! |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

A thinner core with extra turns works about the same as a fatter core with fewer turns. The final overall dimensions may not be all that different. No way of really knowing what is underneath until it is completely unwrapped. Cheers, Tony. |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 816 |

Yeah, I kept checking the model number of the actual inverter to make sure I hadn't mixed them up. My first two were one of each, then the third was another smaller one ... and the fourth was a bigger one. No question that the smaller ones are wound far more tidily and was no surprise that the first large one had burnt windings ... could easily have been through damage during winding. The second large one also had two joins in the windings. Bit of a surprise that they miscalculated and had to join the wire ... or maybe they damaged one during the wind and had to splice in a new bit. Either way there's no drama, just handy to know. I'm sure both sizes were good for their stated 3000VA ... but in our context of using the bare cores ... the bigger cores allow us to get a higher output from our rewinds ... or am I missing something. To give you some idea ... the smaller one has a cross sectional area of 29.75 sq cm ... and the larger one 36.75 sq cm ... that's 20% bigger. Happy to be corrected here ... just trying to understand the ins and outs.  Cheers, Roger |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Potentially, yes. Bigger core means fewer turns required, and/or more winding space. That may enable thicker wire to be used which means more current with less heating. Safe temperature rise is what sets the final limit to power. Cheers, Tony. |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 816 |

Ahh okay, thanks for that. I'm slowly getting it. So that fits in with what you explained a while ago about the current rating of the wire ... where it depended on the ability to get rid of any excess heat ... and that torroids are a good choice because they can be cooled reasonably well with air through the centre. That leads me to a new question then. I am wondering what is an expected top temperature for one of these transformers once they've been rewound? The reason for the question is because I have realised the secret (for me anyway) of winding a neat transformer, is to mark out and wind the first layer accurately ... and then any subsequent layer just falls into place. So I was considering instead of using plywood washers at top and bottom ... to 3-D print some about 5mm thick and rounded edges ... but also print in the troughs and ridges for the first layer. I know, it's probably classed as cheating but I don't mind.  Then of course the question is, will the 3-D print material stand up to the heat and pressure of a tightly wound toroid. Definitely don't want it collapsing after a few years and loosening off all the windings so they rattle to bits. Cheers, Roger |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

There is no simple correct answer to that. I suppose it depends on the temperature ratings of the wire, and any other insulation. The very best grades of wire can be rated up to 200 Celsius absolute maximum. The hottest part (hot spot) will be buried inside the windings, and can run a lot hotter than surface temperature. I suppose if it feels too hot, and there are hot smells, that is probably getting pretty close to what I would consider acceptable, but that is just my own rather conservative opinion. Quite often a full transformer specification will include a temperature rise figure at full continuous rated power. There are also industry standards for various applications in different countries. Its all a bit of a grey area really. I personally do not like hot smells which usually start at about 80 Celsius surface temperature. And that applies to heatsinks as well as wire wound resistors and transformers. There is a secondary issue here as well. Something that gets very hot may work perfectly well, but it may cause long term reliability issues for other nearby more sensitive electronic parts. If you stick with the recommended current density in the wire of four amps per mm square, that will run continuously like that without excessive temperature rise, and at considerably more for short bursts. So once you have worked out your wire sizes that will fit the core, the current density figure x mm sq x voltage will give you a nice conservative transformer power rating. Edited 2021-03-13 19:13 by Warpspeed Cheers, Tony. |

||||

Revlac Guru Joined: 31/12/2016 Location: AustraliaPosts: 964 |

A 3D printed spacer should work ok, depending on the type of materiel used and expected heat, I have printed in ABS with .8mm nozzle in draft mode, was fast and surprisingly neat and tidy on all the flat parts, overhangs and retractions where hopeless, could be fixed but was unnecessary for the job. I had thought the first and second layers of wire could be backed in to the print a little before the next winding, there would no movement or vibration at all, how well it will work or last is a bit unknown. It depends on what you read on the web about transformers and cooling, The toroid all wound up has very little hole left in the center if any at all, Its more of a big solid hot lump, I have seen smaller ones bonded to a large heatsink, I really don,t think any of us are going to cook them, we would check it to see if we need any extra cooling, fans or oil cooling system quite common. Cheers Aaron Off The Grid |

||||

| Murphy's friend Guru Joined: 04/10/2019 Location: AustraliaPosts: 602 |

The remaining hole size depends entirely by what kind of primary wire (cable?) you have used. For my single transformer inverters I used rectangular enameled copper wire and that left plenty of hole, even with the large double stack core that has a 6 x 15mm sq in parallel (90mm sq) primary. For the warpverter I used twisted (6 outer, one center strand) enameled copper wire which was the second hand wire unwound from the aerosharps. A great way to use up leftover wire. Roger, you are not the only one to discover the 3 in parallel, very hard to unwind, aerosharp toroids. Since you have a choice just join two same size cores for the double stack. A hint for that joining, make a PVC tube center that fits exactly into the hole to align both cores as you epoxy them together. You do *not* want any mis- alignment here. You also do not want the cores to come loose as you move them around while winding so epoxying is a *must* in my book. |

||||

| Murphy's friend Guru Joined: 04/10/2019 Location: AustraliaPosts: 602 |

Regarding the heat rise, from my experience the temperature inside my fully enclosed (fan cooled) inverters stays around 10 degrees above ambient. The fan is set to come on at 50 degrees and does so only on very hot days. |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 816 |

Thanks Tony. I am definitely not one to explore the limits with overloading equipment ... it was only when I was asking advice of a 3-D printing expert about the possibility of printing the spacers ... ... and of course his first question was just how hot the transformer would ever run because most filaments are fairly low melting point ... and the better materials really need a professional machine to successfully print them without warping etc. From the transformer labels I showed on page 5, we see they are " Class B". The only temperature class table I could find showed Class B as good for 130 degrees C and an 80 degree temp rise. https://sound-au.com/xfmr2.htm#s115 Yeah, well I don't know enough to question and was very happy to have taken your advice on all those things anyway.  I will definitely be monitoring temperatures very closely and can see the value of a powerful fan setup like you have. At least then if temps do start rising uncomfortably I can hit it hard to try and keep it down. The further I get into all this, I can see it is more of an art than a science.  Cheers, Roger |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 816 |

Thanks Aaron, the 3-D printing expert I spoke to this morning was very helpful and pointed out that my PLA filament melts at 50-60 degrees C and PETG at 80 degrees Polycarbonate will start to soften at 113 degrees. Then he asked specific details of the shape and suggested that at 230 OD by 5mm thick ... there's every chance the print will warp and come unstuck from the table. I didn't get the impression he was trying to talk me out of it ... just genuinely explaining the issues I might face. Seeing there's a lot riding on it, I reckon I'll just use plywood like Klaus did. Hate to have to wind a second one coz it stuffed up.  Cheers, Roger |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 816 |

Square or rectangular wire sounds awesome, but I hate to think how much it would cost or where to even find some. I did follow your comments and photos to twist some wire to make a secondary winding for a spot welder ... but of course in my usual fashion of overkill I used 20 x 1.7mm wires. It was only 2 metres long, but I'll never do that again.  Having said that, with the correct size and shape spacers I reckon I could twist it ok ... but needs a bit more thought put into it first ... and maybe an adult helper too. Yes, I reckon I will do it that way. In fact I was considering using pvc tubing as the spacer between the core and the first winding anyway ... so I can leave it in there. That's very helpful thanks too. Nothing beats real world figures and at least it gives something to go by. Here's a shot of my spot welder cable helper.   Cheers, Roger |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Probably the worst type of load for transformer heating would be airconditioning. That could run constantly for many hours on the very hottest of of days. I asked my mate, the guy that wound my own Warpverter transformers about heating. He said at 5Kw it would take about three hours at full load to reach final maximum temperature for the largest transformer, and that would be about 40 Celsius over ambient sitting in free air without a fan. That is a shell type transformer using E and I laminations which is worse than a toroid for dissipating heat, and it was wound for four amps per mm sq current density. I arranged things so that my air blower blows onto the middle of the vertical heatsink. Half the air blows up along the heatsink channels, and half straight down along the heatsink onto the transformers to stir the air. In over three years of occasional 40 Celsius days, the air blower has NEVER come on. I cannot recall anyone here ever having serious transformer overheating problems. Transformers of this size will absorb a lot of heat just through the sheer mass of copper and steel for a surprisingly long time. They also take a long time to cool down. So for the occasional very heavy load, such as large power tools, an air compressor or welder for example, the load could be huge for several minutes at a time, with rest periods in between. Heatsinking the mosfets will be a bigger problem than the transformer, there is much less thermal mass. Cheers, Tony. |

||||

renewableMark Guru Joined: 09/12/2017 Location: AustraliaPosts: 1678 |

I have had two air cons running basically all day while sun was up, I can't remember top temp, but they have never got to 60c from memory. The way I do mine with the polyurethane, the temp seems to permeate well from the centre, they take a long time to cool down too but that doesn't matter. I wouldn't worry about them getting too hot, prob the last thing to stress about. Chinese transformers in Aerosharps!!!!!!! BEWARE. Some I have got were the same, some were different, luckily I have had mostly a good run, but I got two couriered from interstate a while ago, they were both labelled as 3KW so it wasn't the sellers fault, but immediately when I saw them they looked very small. Stripped them down and they were only 2KW cores, so looks like some were fitted with undersize transformers from their crappy QC factories. Had I known that's what they were I never would have bought them or paid the courier fee from interstate. Cheers Caveman Mark Off grid eastern Melb |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 816 |

We don't use our aircon at all really, which is just as well as it is a huge thing ... but it would be nice to occasionally. And I wouldn't mind fitting one to my workshop as that is where I spend a lot of time, just for the really hot and the really cold days. I don't see our loads as particularly heavy, just lots of varied and consistant ones. I never got the impression any where in all these threads that I needed to be too worried about transformer loads ... especially once I realised the difference between HF inverters and these older style transformer type. Seems that most transformer types can be overloaded heavily for short bursts, which suits me fine. Nothing worse than knowing your system has a definite, sharp and finite limit which if you overstep the mark will blow to bits instead of providing a bit of warning in the way of temperature rise. It will certainly be easier once it has a few miles under its belt to know where it's at and if certain loads affect it more than others. Cheers, Roger |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 816 |

Yeah, thanks for that. All these comments add to my confidence that the transformers will be perfectly ok ... and especially Tony's example where his fan hasn't come on in three years. If it was anyone else I might be wondering if the fan circuit was ok ... but that's not something we need to worry about with Tony.  I had been of two minds with the polyurethane, wondering if blocking off all potential of air permeating the windings was a good thing or not. I suppose it depends on how well it transfers heat or if it holds it in. Either way I can't argue with your results ... especially seeing you have those temperature figures and all those operating hours. I thought the same thing as you to start with, but I've never stripped a 2kW transformer to know what the actual size of a core is. Can you tell me the dimensions of a stripped 2kW core? Cheers, Roger |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

We think much alike Roger. My workshop is quite small, its partitioned off at the back of a two care garage, and I have an airconditioner and gas space heater in there. It heats up or cools down in minutes, and its a very comfortable place to be at any time of year. In Melbourne we might get about four days a year where its 40+ Celsius, and my four airconditioners see very little use. I run my airconditioners from the grid, the big ones during the day, and a small bedroom airconditioner at night, always off the grid. The yearly cost of doing this is negligible as useage is so infrequent. The small workshop airconditioner runs from solar during the day, which is the only time I am ever out there. If its 40+ and the grid goes down, which it has done several times, I just find something to do out in the workshop. Cheers, Tony. |

||||

| Murphy's friend Guru Joined: 04/10/2019 Location: AustraliaPosts: 602 |

Re rectangular wire source, I went to a motor winder to ask if they had leftovers. He mentioned that just down the road was a place that *made* this wire. They make only to order and the minimum was 20kg. But (having pity on me) they said they always make more than ordered and if I was not fussy about size they'll look if some leftover was around as it only got sold for scrap value. I said I'd happily pay a little more than the scrap value and so obtained my rectangular wire, I think it was about 10kg brand new wire I got for scrap price  . .re your 20 strand twisted wire experiment, I tried something similar but fewer strands and quickly saw that holed disk idea was a waste of time if one wants a neat result. I know, somebody here did a many strand primary but it definitely was not neat. Do do it neat, wind 6 strands around a straight (kept straight) single strand and you end up with 7 stand wire. Do another two of these and then wind the 3 x7 into 1 x 21 wire. If you are happen to be in Perth WA you are welcome to have my 7 strand winding disk, spools & all but, of course, no wire on them  |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 816 |

Haha, thanks for the compliment Tony, I just wish I also knew as much about all this technical stuff as you do.  I spent nearly 30 years working from a little tiny workshop about 10 x 30ft and only 6 years ago moved here where I enclosed a section of a big shed into a 20 x 30ft workshop ... all nicely lined and insulated. It would be nice to have a reverse cycle in there for the extremes of weather coz I spend all day working out there ... and many nights working on projects or catching up on work. Summer atire can be shorts and thongs ... and winter, long johns and beanie etc. It's gunna be great having enough solar that I don't have to feel guilty using an aircon when it's needed. Cheers, Roger |

||||

| rogerdw Guru Joined: 22/10/2019 Location: AustraliaPosts: 816 |

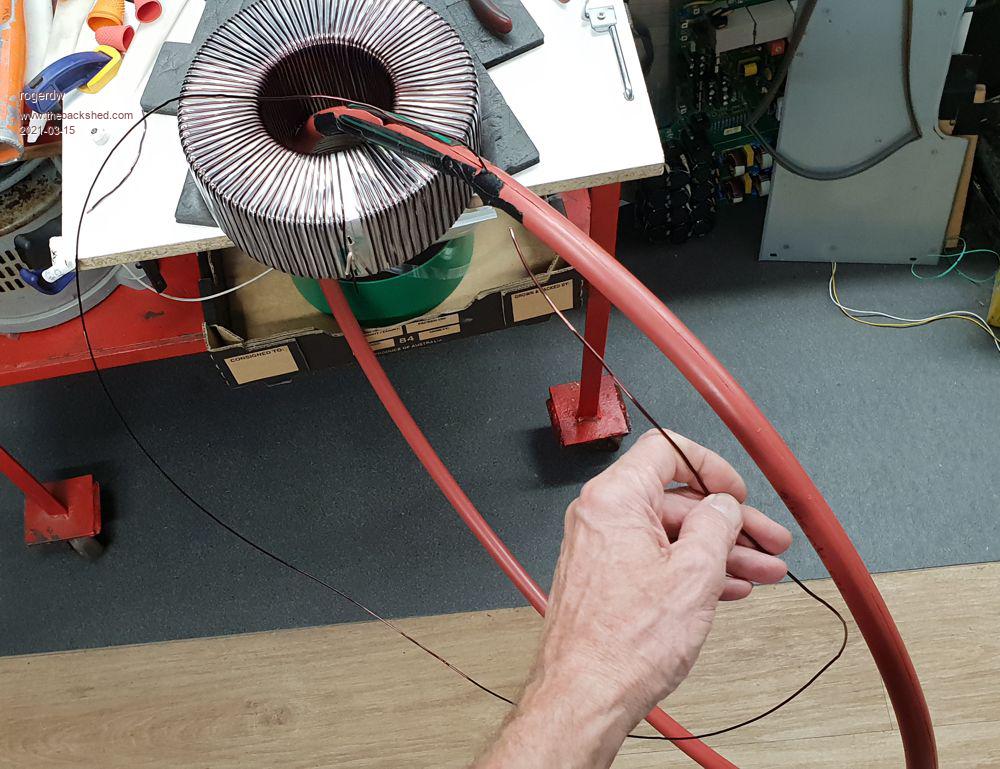

Great find there. What a bargain. Surprising what is around once you start asking questions. I think if my disk was much bigger diameter or perhaps had handles to provide some leverage, I might have had a better result ... but I like your suggestion of winding some 7 strand wire and then combining 3 of those. I did watch some rope making videos but that would be hard to replicate with copper wire I reckon. Looks like it may be time to spend money on some larger insulated cable and be done with it. It's a bit hard to see from the photo but the loop of wire I'm holding is all that's left of the wire I loaded in my hoop after finishing two layers. It was a 50 metre length unwound from a 3kW tx and I was sweating as I got close to the end worrying that I might have to join a bit on to finish my layer. I have another 2 lengths at 52.5 metres and 57.5 metres. They should both do two layers each ... but do need to be longer as the diameter grows. This is the #2 Tx (I've completed the main winding on #3 and #4) ... ... 2 layers down with 5 to go. I'm using 1.7mm second hand wire instead of the new 1.8mm which I'm saving for #1 transformer.  Cheers, Roger |

||||