| Matt Lyons double stator F&P windmill. |

|

Email and pics from Matt about his own F&P creation.

I have been working on F&P Wind Turbines for about

3-4

years and started of with 10 amps in gail force winds,

until recently when i got a massive 40+ Amps @ 14Volts

=560watts with two motors on the same shaft.

When i was using a single motor i had it wired in

series/parallel with delta output and 1.8M diametre

3 blade rotor, I got 25 amps at 10m/s but was not good

in light winds around 5-6m/s and was getting noisy in

high winds due to higher rpm's.

Since going to the two motor setup i have tried the

two motors in delta to get a potential 60amps but you

need a larger rotor to get 600+ watts, and a large

rotor wont spin fast enough to get the 60 amps.

I now use star output giving me a total of 40+amps,

with a larger 2.2M rotor which works well in light

winds giving me 1-2amps at 3m/s, 5A at 4m/s, 10A at

5m/s, 15A at 6m/s, 20A at 8m/s, 28A at 9m/s,

30-35A at 10m/s with a peak of 40+ Amps.

I log the output via a Plasmatronics PL20 reg and a

anemometre data logger connected to a laptop.

Attached are some Pics of the turbine

(rough construction but strong).

Note: Changing the pitch on my blades by just

2-3 degrees makes a lot of difference to the output,

and even more so with my smaller 140 watt 1.2M rotor

small turbines.

I also build Stirling engines for fun.

If you are interested in testing my small turbines

which are a rewound car alt with rare earth magnets

and small PVC blades 1.2M Diametre.

They put out 10 Amps at 10m/s and up to 15A in very

strong winds, they have very little cogging and start

in very low wind speeds, putting out .5-1A at 3-4m/s.

They weigh only 5kg, which would not cost much to

transport if you want to test one for a month or so.

I am looking at selling them as a kit and would like

your opinion on them.

Finally as you will see in the pics, I mount each

motor at each end of the shaft.

With your method and mine you could make a 4 motor

turbine.

I'm glad you like the pics, lately in

melb i have been

getting an average wind speed of 3m/s and getting

30-50amp hours/day on average, in the past with one

motor i was lucky to get 1 a/h in 3m/s av wind.

I was also concerned about the flex

in the magnet

rotor when bolting blades to it, but i use a 6mm

aluminium plate cut round with a jigsaw to mount the

blade extensions and blades.

The blades don't flex much due the smaller size

850mm/7mm blades with blade extensions, I find using

5mm PVC they tend to flex and go out of shape,

reducing power output in higher winds.

I would be more than happy for you to

put my photos

and details on the web.

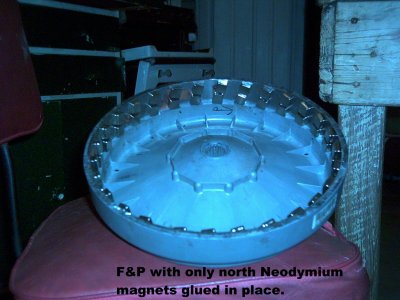

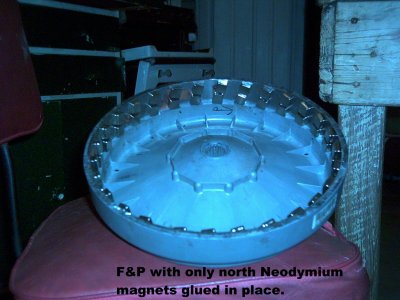

My latest venture is to take off the

weak ferrite

magnets and replace them with 6.6mm rare earth

magnets,

equals about 6-8 times the magnetic strength.

Westwind also did this with the old 2.5kw turbine and

converted the alt to 5kw with the use of rare earth

magnets instead of ferrite.

When making the small modified PMA car

alternators, I

found that the coils were half the size of the F&P

and

only 12 coils per phase wound in series with .8mm wire

and i can get over 10 amps at 600rpm, I think this is

due to the 20mm/12mm/6.5mm rare earth magnets, which

are far more powerfull than the F&P ferrite or white

magnet rotor with small rare earth magnets.

I have done the conversion lifting of the old ferrite

magnets with a gas flame and screwdriver and replacing

with 11mm/30mm/6.6mm rare earth magnets.

The problem is that the grey rotor goes out of shape

when i try to put it on the stator, this is due to the

extra strong magnetic feild, and i am trying to work

out a way of strengthening the magnet rotor to avoid

this poling out problem.

I expect a lot more power and maybe less cogging

because i mounted the magnets on an angle to avoid

cogging.

I will let you know how i go, if it

works well i might

sell the rotors as a hot up kit for F&P's.

I expect 2-3 times the power output, but am concrerned

about the plastic rotor, would like to make one out

of

steel.

For the last year or so i have used

bosch car alt's,

but you need to rewind the stator using smaller wire

more wingings, with 10A @ 10m/s.

With the truck alt's, they are 1kw and have a larger

stator with the correct amount of windings in heavy

gauge wire for use with 12 volt systems, you would

need to rewind the stator if you require 24 or 48

volts, as the speed would be too high for a turbine.

Larger magnet rotor area also increases power.

As i mentioned the new truck alt will put out up to

25-30A @ 10m/s with a 1.5M rotor. In higher winds it

could put out up to 40A which is its rating.

Go to the wreckers and ask for old ones that don't

work, eg: bad reg or brushes etc as you don't need

them.

I have worked out a cheap easy way of converting the

original exciter coil rotor into a permanent mag

rotor.

Matt Lyons

matlyons@yahoo.com.au |