|

|

Forum Index : Windmills : Swapping out the stock magnets?

| Author | Message | ||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

Has anyone ever swapped out the stock magnets for a stronger Neodynium type? This could definitely be done. For example, my Samsung unit has 4 mag poles per brick, with a 36 pole stator ( probably helps with decogging, 3 coils per 4 pole of magnets). Each pole is approx 30mm long x 18mm wide x 5mm thick. I can find 25mm long x 15mm wide x 5mm thick Neodynium N35 magnets. What would be the results if I could replace the stock mags with these epoxied in place? |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

Wow OK, so going way way back to the beginning days here (2005) Matt Lyons did just this. This is really cool. I wonder about using the Asian rotors which ARE metal and with a change out of wire to copper with a well spec'd gauge, what that might produce. |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

I have yet to read through every Neodynium magnet conversion/test (the Neo conversion) threads here, but it does seem to be that it kind of faded away into obscurity, either because it's a lot of work/expense and/or little use or practicality to the Wind Turbine usages. I do want to play around with this design idea. I see a few issues, from what I've gathered and from what I know. Magnetic saturation of the stator issues Magnetic Hysteresis within the stator steel laminations Spacing between the magnetic switchings NSN, S N S, N S N.....etc of the rotor, as a result of the enlarged magnetic flux field around each pole piece. Coil wire diameter - current load and heat dissipation. Electromagnet torque - cogging And not to forget to mention the mechanical difficulty in assembling the rotor onto and off of the stator, due to the extreme increase in magnetic interaction. Edited 2021-04-18 04:54 by Kamak |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

It sure will help everyone that is interested in this conversion idea, if we start with well documented data. The magnetic flux density of the magnets used. The RPM/Voltage curve. RPM/Current curve, The inductance of the coils groups, The resistance of the coil groups, Copper wire diameter, the number of turns per coil, the number of magnets vs the number of coil poles. Edited 2021-04-19 02:17 by Kamak |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

The most important design consideration (the most obvious and undocumented) when rebuilding the rotor with new magnets, is that all the coil/poles within any one phase leg see the exact same magnetic polarity (and transition from/to +-, polarity phase change), at the exact same time. This is where hysteresis, magnet spacing, and speed of rotation should get consideration. |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

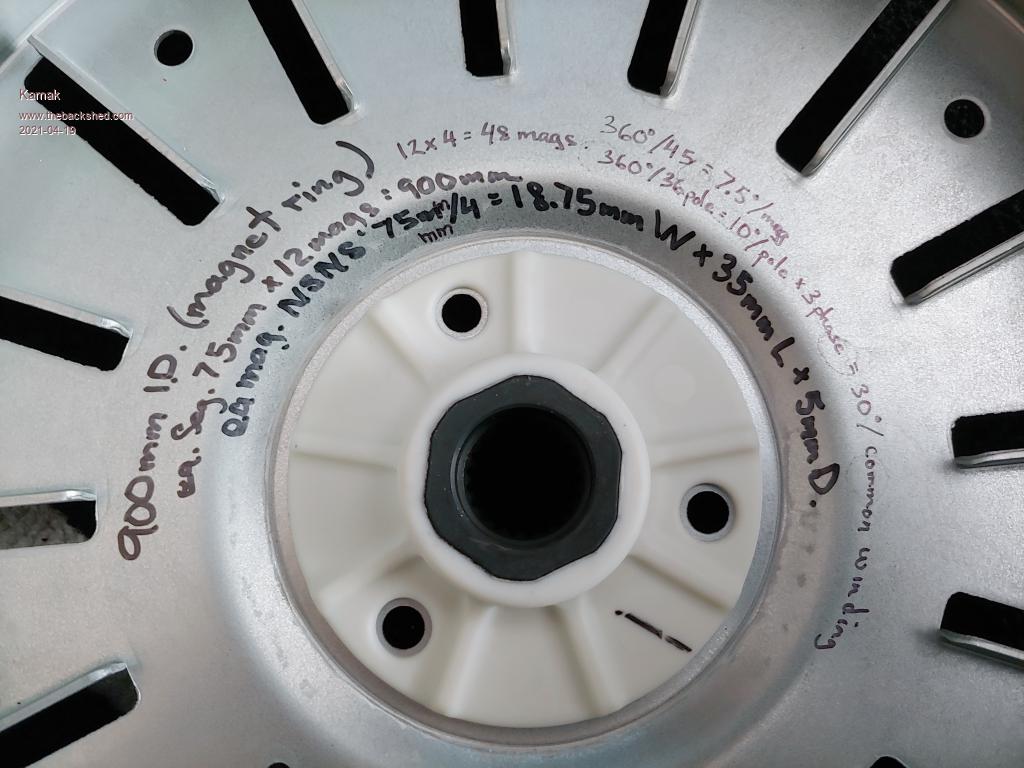

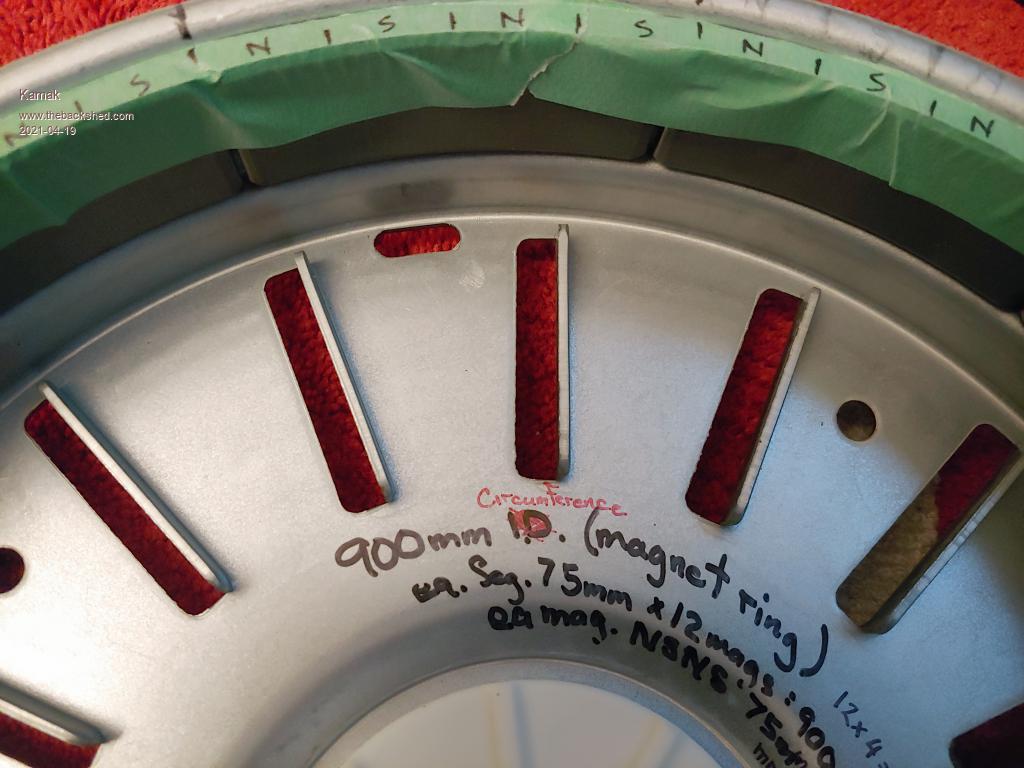

Stock Samsung P/N: 09CA49132 Stator 900mm ID. Mag ring 75mm W x 35mm L x 5mm Thk mag bricks 12 mag bricks 4 poles per mag brick NSNS 75mm/4 = 18.75mm W magnets 35mm L x 18.75mm W x 5mm Thk per mag pole 48 mag poles @ 7.5deg per pole, 15deg per "like" polarity Stock mag flux density = approx 1750/1800 Gauss 36 coil poles = 360deg/36 = 10deg per coil pole 3 phase winding XYZ = 30deg per "common" phase winding 15deg per mag pole of "like" magnet polarity 30deg per "common" phase winding therefore the "like" magnetic pole polarities (and transitions thereof) will always aline with the "common" coil windings throughout rotation, as 15deg is an even common denominator of 30deg.   Edited 2021-04-19 06:08 by Kamak |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

https://www.thebackshed.com/forum/ViewTopic.php?FID=2&TID=22 |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

15deg of arc per mag pole(centerline) of "like" magnet polarity 3.75deg+ 7.5deg +3.75deg N | S | N = 15deg C|C N|S|N|S @ 30deg of arc per mag brick 30deg per "common" phase winding therefore the "like" magnetic pole polarities (and transitions thereof) will always aline with the "common" coil windings throughout rotation, as 15deg is an even common denominator of 30deg. Increasing the magnetic strength (N35, N50) of each magnetic pole piece with Neo types and the width of each magnet piece, will increase the flux field width around each pole piece, which will require increasing the spacing between each pole piece. Even if each new magnet was the exact same dimensions (18.75 mm x 35mm x 5mm) it would most likely still require a greater spacing between centerlines. Decreasing the width of each magnet while maintaining a greater flux density could help maintain the stock spacing. This will all require some good ol trial and error bench testing. 5mm cube N40 magnets can be acquired. This will allow for quick and uniformly placed and changed out magnetic pole widths and spacings. |5|5| |5|5| |5|5| |5|5| 10 x 35 |5|5| |5|5| |5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| 15 x 35 |5|5|5| |5|5|5| |5|5|5| |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

|----------30deg of Arc---------| |--------------75mm--------------| |5|5|5|5|5|5|5|5|5|5|5|5|5|5|5| N S N |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |6deg|6deg|6deg|6deg|6deg| | 3 |6deg|6deg|6deg| 3 | This scheme does not work C|C (center to center) of like poles is: 3deg + 6deg + 6deg + 6deg + 3deg = 24deg The magnetic poles would be misaligned with the common phase winding-core pole 30 deg is not evenly divisible by 24 With the stator core poles @ 30deg C|C the rotor mag poles of the same polarity must be either 15, 30, 60 or 120deg C|C. I'm not 1000% sure about this right now. Edited 2021-04-19 11:22 by Kamak |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

|----------30deg of Arc----------| |--------------75mm--------------|--------------75mm--------------| |5|5|5|5|5|5|5|5|5|5|5|5|5|5|5|5|5|5| N S N |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |6deg| 6deg |6deg | 6deg| 6deg| Edited 2021-04-19 11:43 by Kamak |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

https://www.thebackshed.com/forum/ViewTopic.php?FID=2&TID=328 https://www.thebackshed.com/forum/ViewTopic.php?FID=2&TID=22 |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

Hi Kamak. Maybe I'm not rearing all your posting ,, but you say the outside diameter of your rotor is 900 mm ?? Am I wrong ?. I thought they (Fisher and Paykel ) rotors are around 240 mm or a bit larger. (I would have to dig one out from my F&P box of tricks). I've ,many years ago , fitted Neo"s to the rotors , fairly easy, lots of small 25mm X 5mm X 3mm (I think). made a big difference. Can"t remember the figures now ,as most of us have gone SOLAR . I've still got heaps of F&P stuff ,one day I might drag it out and hoist a mill om my tower. (sort of gone solar , now days. had lots of fun years ago , but I'm a Museum old fart nowadays, so playing with towers and winches is sort of ,,, memories !!. I wish you fun Bruce Bushboy |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

Yeah, My bad! this is a Samsung rotor. The diameter that I am referring to is the inner circumference of the rotor where the magnets are glued to, 900mm in this case. Sorry about that. I sure wish I could go back in these threads and make corrections. Seems that you can only make corrections to the last post as long as no one else has posted after you. No biggy, I will correct when and where I can, and with follow-ups. |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

Stock Samsung P/N: 09CA49132 Stator 900mm [Internal Circumference]. Mag ring 75mm W x 35mm L x 5mm Thk mag bricks 12 mag bricks 4 poles per mag brick NSNS 75mm/4 = 18.75mm W magnets 35mm L x 18.75mm W x 5mm Thk per mag pole 48 mag poles @ 7.5deg per pole, 15deg per "like" polarity Stock mag flux density = approx 1750/1800 Gauss 36 coil poles = 360deg/36 = 10deg per coil pole 3 phase winding XYZ = 30deg per "common" phase winding 15deg per mag pole of "like" magnet polarity 30deg per "common" phase winding therefore the "like" magnetic pole polarities (and transitions thereof) will always aline with the "common" coil windings throughout rotation, as 15deg is an even common denominator of 30deg. Mod (experimant) |-----------30deg of Arc---------| |-------------75mm---------------|-------------75mm-------------| |5|5|5|5|5|5|5|5|5|5|5|5|5|5|5| 5mm = 2deg arc N S N |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |5|5|5| |6deg | 9deg |6deg| 9deg | Edited 2021-04-19 13:19 by Kamak |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

|

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

Stock magnet B = 1800 Gauss (as measured with Gaussmeter) Vs Material: Sintered NdFeB. Grade N42 Gauss Rating B: 13,200 Gauss (Not measured, but listed strength) 5mmx5mmx5mm (used = 35mm x 10mm x 5mm, N=7 x 2 x 1=14 magnets)  13,200/1800 = 7.3x increase Does anyone here remember what the Neo Mag strength that is/was used on a successfully rebuilt F&P gen that actually produced as a wind turbine? Spacing, dimensions....etc Edited 2021-04-20 00:51 by Kamak |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

I would love to go through all the Windmill threads and find all the best related posts referring to Neo conversions, and the end results from them. The ones I've found so far, all seem to fade away with not much follow-up on success, and/or the succession of results between related threads don't seem to build off one another, in any concise way. It seems that the conversion might be a great power output inhancer, yet not suitable for successful wind turbine production. I have yet to find any conversions related to the other Asian-built washing machine DD BLDC motors, ie Samsung, LG...The ones that have drawn pressed metal rotors. From 2008, http://www.thebackshed.com/forum/ViewTopic.php?FID=2&TID=920 http://www.thebackshed.com/forum/ViewTopic.php?FID=2&TID=1038#7926 http://www.thebackshed.com/forum/ViewTopic.php?TID=1367 Edited 2021-05-05 08:35 by Kamak |

||||

| Kamak Senior Member Joined: 13/04/2021 Location: CanadaPosts: 150 |

Custom made Neo magnets from China |

||||