|

|

|

Site Navigation

Projects & Information

»General Information»Wind turbine Projects »The F&P Smartdrive »Electronic projects »Microcontroller projects »Miscellaneous Kits & Parts

»Basicly Natural Pty Ltd»PVC & Aluminium blades »Scale model farm windmills »Price Watch Discussion Forums

Handy Links

»Wind»Solar »Electric Vehicles »Electronics »Micro Controllers »General Interrest About TheBackShed Getting Started Privacy Policy |

One of the biggest problems with the F&P is cogging, or the amount of effort required to start the windmill from a stand still. Many a windmill has been built that refuses to start until the wind picks up. But once going, the windmill will make power at much lower windspeeds. The standard F&P stator has 42 poles, and the magnet hub has 56 magnets. This gives us a 3 phase output, but cogging is bad. However later models of the F&P use a new magnet hub, it only has 48 magnets. If we use one of these hubs on a common stator, cogging is reduced to almost nothing. But there is a catch, we need to re-wire the stator to 7 phase. Before we go further, I would recommend you read this page, it describes the process of re-wiring the stator.... http://www.thebackshed.com/windmill/FPRewire.asp Ok, the new magnet hub wont appear on the recycling piles for a few years yet, its only a new model, but you can buy them new for about $60 to $80 from your local white goods agent who repairs F&P gear. The part number you need to ask for is... Part No. 420 774 P The old hubs had 14 large ceramic blocks, each with 4 magnets, giving us 56 magnets. The new hub has 16 ceramic blocks, each with 3 magnets, giving us 48 magnets, and the new ceramic blocks are physically smaller than the old type. The new hub magnets lines up with a stator pole every 7 poles ( where it was every 3 poles with a old hub ).

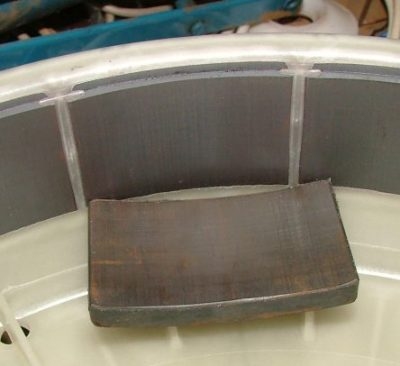

On the subject of tiles, each tile consists of magnets, the old 4 magnet tile to the left, and a 3 magnet tile on the new hubs to the right. There would be two different new tiles, one that goes N S N, and one that goes S N S. We can use out standard re-wire naming scheme as explained on the F&P Stator Rewiring page, and just add "7Phase" to make it clear its a 7 phase conversion. So... Click on the drawings below to see full size. For simplicity each drawing only shows one phase, so you just need to do the same connection for the other 6 phases. The Star connection is a common connection to all phases. You may wonder what the difference in 7 phase power is compared to 3 phase. 7 phase has a slightly higher output voltage peak, and less ripple after rectification. The drawings below may help. V1 is less than V2

Rectification. I threw together a 7 phase bridge rectifier using 4 cheap 35amp bridge rectifiers from Dick Smith, like this...

Special thanks to Bruce. |

||