|

|

|

|

Print Print |

|

|

| Windmill Kit, no longer supplied.. |

|

Tail Assembly

| With the windmill

bearing plate secured level ( normal operating position

) in a vice, slide on the tail assembly. It should point

directly backwards from the propeller. Viewed from behind

the windmill, the tail assembly will rotate to the left

and up. Clamp the tail in place and mark the three drill

holes in the end of the tail arm using the tail fin as

a template. Make sure the tail is vertical. Drill the

holes and bolt on the tail, again making sure the tail

is vertical. |

|

Tail Rope. Tie a length of 5mm+ rope to the end of the tail. This

is used to pull the windmill out of the wind, or unwind

the drop wire every few days, depending on how often

the wind changes direction in your location. Use a tennis

ball on the end of the rope, cut off at about chest

height ( once the windmill is up in the air ).

Yawn Adjustment. The tail can

be adjusted to yawn at higher wind speeds by adding

weight to the tail. |

|

| Final

Assembly |

| Bolt a 3 phase rectifier

( from a old car alternator, click here for more info ) to the bearing plate. The rectifier needs

to be in a open location where it will be cooled by the

wind. Run 3 wires from the stator connections to the rectifier

AC connectors, use 4mm core or better wire. Run 2 wires,

black and red ( - & + ) from the DC out of the rectifier.

This is the Drop Wire, and needs to be long enough to

at least reach the ground from the top of your windmill

tower. Secure the drop wire to the bearing plate with

cable ties, allow a little slack to the rectifier. |

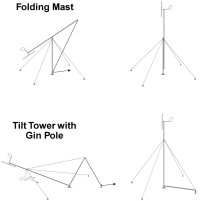

| Mast

Suggestions |

Below are suggestions for mounting your

windmill. There are many links on the internet about

mast design and location. I prefer to use a folding

mast, as it makes windmill maintenance or repair easy.

You windmill needs to be in a open location, away from

or above any building, trees, or anything that may affect

the wind.

Do not mount the windmill on the roof

of your house! The Fisher & Paykel stator generates

a cogging vibration when spun. This vibration travels

down the mast, and can be felt in the ground several

feet from the mast base. If you were to mount this windmill

on your roof, the noise will be unbearable.

We highly recommend talking to your

local structural engineer about your windmill mast.

They will be able to recommend footing requirements

and design, mast construction and any local council

requirements. You local council may require you to apply

for a permit.

But as a rule, build your mast stronger

than you need to. There is nothing more scary that watching

you own windmill during a storm and praying that it

hangs together, and nothing more rewarding when it does. |

|

Next

- Electrical |

|

|

|

|

|

|